Kevlar or Dyneema? It’s the ultimate showdown in protective denim. For apparel brands and manufacturers, this choice defines the market positioning, safety rating, and production cost of your next collection. Kevlar brings legendary heat resistance for heavy-duty applications, while Dyneema offers space-age lightweight strength for premium urban lines. Ready to engineer a bestseller? Let’s cut through the marketing hype and discover which fiber is right for your product line.

What is Protective Denim Fabric?

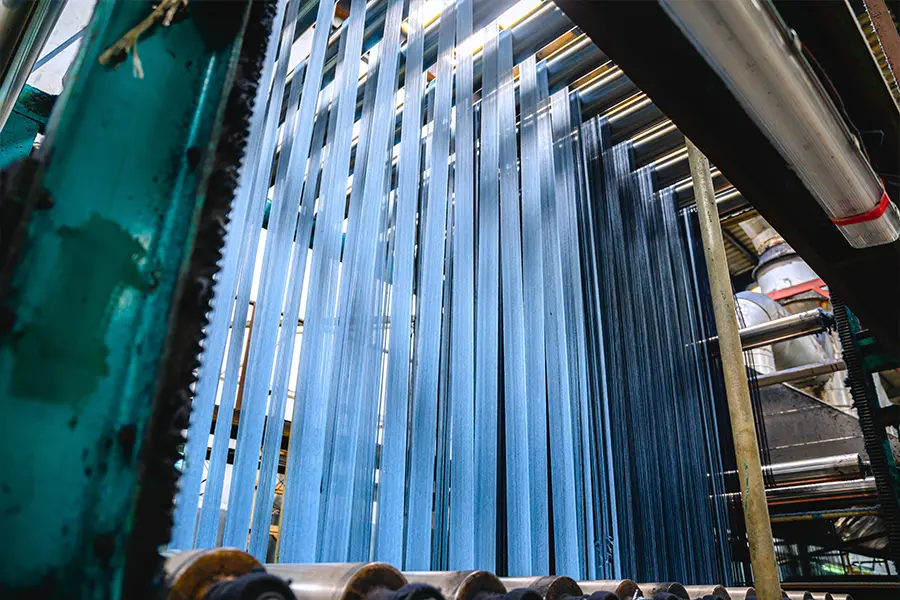

Protective denim fabric is a technical textile designed specifically for heat, flame, and abrasion protection. Unlike standard fashion denim, this specialized textile uses advanced fibers or chemical treatments to meet strict safety standards for hazardous settings. Its main applications are in industrial Personal Protective Equipment (PSA) like flame-resistant workwear and high-performance motorcycle gear.

To make an informed sourcing decision, you first need to understand the two main players in the market.

What is Kevlar Denim?

Kevlar is a para-aramid fiber famous for its heat resistance and tensile strength. In the world of denim, Kevlar is rarely used alone; it is typically blended or used as a lining.

- Composition: Kevlar blend levels vary depending on the end use. Zum Beispiel, 15–30% Kevlar is common for workwear, while 40–60% suits high-protection applications.

- Function: It provides exceptional resistance to heat and cuts. Manufacturers often achieve EN 17092 AA/AAA benchmarks by using additional aramid reinforcements behind the denim shell.

What is Dyneema Denim?

Dyneema® (UHMWPE) is known as the world’s strongest fiber. When integrated into denim, it offers a completely different value proposition: lightweight strength.

- Composition: Dyneema fibers are usually woven directly into the denim warp or weft, allowing for “single-layer” protection.

- Function: It is known for its exceptional strength-to-weight ratio and abrasion resistance, making it ideal for creating durable yet lightweight apparel that feels more like traditional jeans.

Kevlar vs. Dyneema Denim: Key Performance Differences

When engineering a product, you are balancing three main factors: Stärke, weight, and heat resistance. Here is how the two compare.

Stärke & Gewicht: Tensile Strength Comparison

Dyneema® holds the crown for strength-to-weight ratio. It is 15 times stronger than steel at the same weight. This allows for the creation of single-layer jeans that pass safety tests without bulky linings.

Kevlar is incredibly strong but is heavier. To achieve the same abrasion resistance as Dyneema, you typically need a thicker weave or a separate lining layer (resulting in a heavier garment, often 16-21 oz/yd² for maximum strength).

Heat Resistance: Friction and Melting Points Explained

This is the most critical technical difference.

- Kevlar: Has an extremely high melting point and is inherently flame-resistant. In a high-speed motorcycle slide, friction generates immense heat. Kevlar will not melt into the rider’s skin.

- Dyneema: While strong, UHMWPE has a lower melting point compared to Aramid. Jedoch, modern Dyneema denim blends are engineered to withstand road friction, but they do not offer the same fire-retardant properties as Kevlar-based FR (Flame Resistant) Arbeitskleidung.

Komfort & Breathability: Which is Better for Daily Wear?

Comfort is the main reason riders choose one fabric over the other, and this is heavily dictated by the fabric’s construction method.

- Dyneema: Because it offers high strength with less bulk, Dyneema denim is often cooler to the touch and more breathable, making it excellent for summer riding.

- Kevlar: Traditional lined Kevlar jeans can be warm and bulky due to the double-layer construction. Jedoch, newer “comfort blends” are improving this.

Pro Tip: Understanding “Single Layer” Construction

You will often hear Dyneema denim referred to as “Single Layer.” This means the protective fibers are woven into the denim itself, making the jeans feel light and cool, just like regular fashion denim.

Traditionell, Kevlar jeans were “Lined” (or Double Layer), meaning a separate layer of yellow Kevlar fabric was sewn inside a regular pair of jeans. While this offers great protection, it can be bulkier and warmer. Jedoch, modern technology is now allowing for single-layer Kevlar blends as well.

- Choose Single Layer (Dyneema) for maximum comfort and style in summer.

- Choose Lined (Classic Kevlar) for maximum thermal insulation and abrasion density in extreme slides.

Quick Comparison: Vorteile, Nachteile, and Specs

| Kategorie | Besonderheit | Kevlar (Aramid) Denim | Dyneema (UHMWPE) Denim |

|---|---|---|---|

| Vorteile & Nachteile | Vorteile (The Good) |

• Extreme heat resistance (won’t melt) • More affordable & accessible • Proven reliability over decades |

• Incredible strength-to-weight ratio • Cool to the touch & atmungsaktiv • Allows for “single layer” Komfort |

| Nachteile (The Bad) |

• Heavier & bulkier (often requires lining) • Traps body heat (can be hot) • Sensitive to UV degradation |

• Lower melting point (heat sensitive) • Significantly more expensive • Low elasticity in pure form |

|

| Tech Specs | Fiber Composition | Para-aramid fiber | Ultra-high molecular weight polyethylene |

| Melting Point |

> 500°C (> 930°F) (Does not melt, decomposes) |

~ 145°C – 152°C (~ 293°F) (Can glaze/melt under high friction) |

|

| Tensile Strength | Ca. 5x stronger than steel | Ca. 15x stronger than steel | |

| Typical Fabric Weight |

Heavy (14 – 24 oz) (System weight: Denim + lining) |

Light to mid (12 – 15 oz) (Single layer fabric) |

|

| Safety Standard | Common in AAA / AA rated gear | Common in AA / A rated gear |

Elevate Your Brand: Bespoke Denim Manufacturing

How to Choose between Kevlar vs. Dyneema Denim

Your choice shouldn’t just be about “which is stronger,” but “how will the user wear it?” Different activities, safety risks, and environments demand different material properties.

When to Choose Kevlar?

Am besten für: Highway touring, track racing, and hazardous industrial environments.

- For Motorcycle Safety (Abrasion & Heat): In high-speed scenarios, a slide on asphalt generates immense heat. Kevlar’s thermal stability (>500°C) is non-negotiable here—it will not melt into the skin during a slide.

- For Industrial Workwear (FR & Schneiden): Kevlar (Aramid) is the gold standard for Heavy-Duty Workwear. If your end-users are welders, electricians, or oil rig workers facing risks of flash fires, arc flashes (NFPA 70E), or sharp cuts, Kevlar denim blends offer the required protection that standard cotton or polyester cannot provide.

When to Choose Dyneema?

Am besten für: City riders, skaters, and active wear that demands lightweight durability.

- The Logic: Users who prioritize mobility and comfort often reject heavy, lined gear. Dyneema’s high strength-to-weight ratio allows for single-layer construction.

- The Application: It creates a jean that looks, verblasst, and breathes like a vintage Levi’s 501 but offers industrial-grade abrasion resistance. This is the gold standard for “Lebensstil” protective gear, where the user needs to move freely without being weighed down.

How to Check Denim Fabric Quality and Safety Ratings

To check Denim-Stoff quality for safety ratings in 2026, you must verify compliance with international standards.

Key Safety Standards

- EN 17092 (Motorcycle): This standard classifies denim riding jeans into AAA (High speed/Heavy duty), AA (Touring/Medium duty), A (Urban/Light duty), B, or C classes. A denim fabric classified as “AA” offers significantly higher abrasion protection than an “A” class fabric and is the most common target for premium denim gear.

- Workwear Standards: Look for NFPA 2112 (Flash fire) or EN ISO 11612 for thermal protection.

Essential Fabric Performance Tests

Manufacturers like Changhong utilize rigorous lab testing to ensure compliance:

- Impact-Abrasion: Using machines like the Darmstadt to assess time to hole formation (crucial for EN 17092).

- Tear Strength: Evaluated using ASTM D751 (tongue tear) or ASTM D5733.

- Chemische Sicherheit: Confirmed via OEKO-TEX STANDARD 100, ensuring the denim is free from harmful substances.

Where to Source High-Quality Protective Denim

Sourcing the right fabric is as important as choosing the right fiber.

Sourcing Kevlar Denim

Manufacturers sourcing Kevlar denim should look to textile jobbers for yardage or B2B platforms like Alibaba for mill-direct rolls.

- Key Specs: Focus on specific blend percentages (Z.B., 15-60% Kevlar) and fabric weights (12-16.5 oz).

- Where to look: Platforms such as Alibaba host numerous suppliers offering Twaron and Kevlar blends. Specific examples include Big Z Fabric’s ‘Sporting Kevlar Selvage Denim’ (16.5 oz).

Sourcing Dyneema Denim

Sourcing genuine Dyneema® denim typically involves working with specialized approved partners, as direct consumer purchase is uncommon.

- Partners: Look for specialized industrial mills like IBQ, Lenzi Egisto, Naveena Denim, or Toyoshima.

- Anpassung: Factories like Changhong offer custom production (OEM/ODM), allowing you to integrate Dyneema fibers into custom weaves, Wäsche, and styles with low MOQs.

Why Choose Specialized Factories for Performance Denim?

Crafting denim that meets high functional standards requires more than just good design; it requires treating fabric creation as an engineered system.

- Precision Engineering: Specialized mills apply numeric gates at each stage—from warp sizing (improving abrasion resistance) to beam moisture control (stabilizing tensile properties).

- Advanced Processes: They use specific techniques like controlled singeing and core-spun cotton-spandex yarns to ensure the final product meets “Real World” performance demands.

Bring Your Vision to Life with the Right Partner

Understanding the technical differences between Kevlar and Dyneema is crucial, but it’s only half the battle. The real challenge for any brand is securing these premium materials and finding a manufacturer skilled enough to handle them.

You don’t have to navigate this supply chain alone.

Mit Over 20 jahrelanges Fachwissen, Changhong is more than just a factory—we are your strategic partner for high-quality custom denim manufacturing. We offer comprehensive one-stop solutions, meaning we handle everything from sourcing the exact performance fabrics (whether Kevlar, Dyneema, or specialized blends) to precision cutting, Nähen, and sustainable finishing.

Whether you are an emerging label or an established brand, our advanced facilities and commitment to sustainability ensure your protective gear meets the highest global standards. Don’t let material sourcing slow you down. Let us turn your technical concepts into a market-ready reality.

Häufig gestellte Fragen

Which is more expensive: Kevlar or Dyneema denim?

Dyneema definitely commands a premium price due to its advanced single-layer technology. Kevlar is more established and affordable, making it the smart, cost-effective choice for mid-range protective product lines.

How does Cordura denim compare to Kevlar and Dyneema?

Think of Cordura as the “Entry Level” champion. It is affordable and durable, but lacks the extreme tensile strength of Kevlar or Dyneema. It is perfect for budget-friendly urban gear.

Can these fabrics be washed like regular jeans?

Ja, but treat them gently! Use a cold wash cycle and always air dry. Avoid high-heat dryers, especially with Dyneema, to protect those high-performance fibers from degrading.

What is the lifespan of protective denim?

The protective fibers can last for years if not crashed. Jedoch, keep Kevlar away from direct sunlight when storing, as UV rays can degrade the aramid fibers over time.

Is “Single Layer” denim better than lined denim?

It depends on the goal! Single Layer (Dyneema) wins for summer comfort and style. Lined (Kevlar) wins for maximum thermal insulation during a high-speed slide. Choose based on your climate.