E Changhong, nos concentramos na produção de roupas jeans de alta qualidade, refinando cada etapa do processo de fabricação. O jeans pode ser tingido usando vários métodos, incluindo tingimento de corda, tingimento de terror, batik, tingimento cruzado, tingimento de cuba, tingimento de fios e tingimento de peças. Entre estes, tingimento de corda e tingimento slasher são os mais comumente usados para fios.

Este guia detalha tudo o que você precisa saber sobre essas duas técnicas de tingimento índigo. Você verá como cada método funciona, o que os torna únicos, e qual deles se alinha com sua visão. No final, você terá clareza para escolher com confiança e seguir em frente com seu projeto.

Resumo das principais diferenças

Antes de mergulhar nos detalhes, aqui está um instantâneo rápido:

| Critérios | Tingimento de corda | Tingimento de Slasher |

|---|---|---|

| Penetração de corante | Profundo e gradual, criando variações de cores ricas | Nível de superfície, cor consistente, mas profundidade menor |

| Profundidade de cor | Rico, tons dinâmicos que desaparecem naturalmente com o tempo | Até, tons uniformes com menos variação no desbotamento |

| Textura de tecido | Mais suave, sensação de mão mais luxuosa, mantém slubs | Um pouco mais rígido, variedade de textura limitada |

| Velocidade de produção | Mais lento devido a múltiplos mergulhos e ciclos de oxidação | Mais rápido, adequado para produção em larga escala |

| Custo | Maior devido ao trabalho, água, e intensidade de tempo | Mais baixo, mais econômico para produção em massa |

| Sustentabilidade | Maior consumo de água e corante, pode ser otimizado | Menor uso de água, redução de resíduos químicos |

| Melhor para | Prêmio, jeans de edição limitada com desbotamentos de alta qualidade | Jeans produzido em massa com cores consistentes e eficiência |

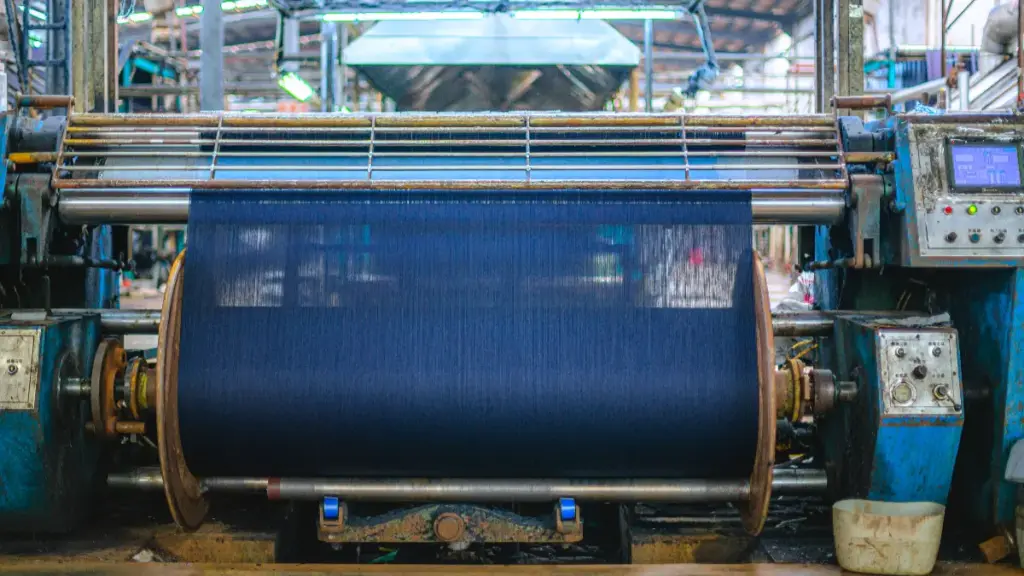

O que é tingimento de corda em jeans?

O tingimento de corda é um método tradicional de tingimento de fios usado para criar jeans premium. Neste processo, vários fios são torcidos juntos em cordas e repetidamente expostos ao corante índigo. O corante penetra principalmente nas camadas externas, deixando o núcleo um pouco mais leve. Isto resulta em profundo, cores ricas e características únicas de desbotamento ao longo do tempo. O tingimento de corda é valorizado por produzir texturas, jeans de alta qualidade com toque macio e cor duradoura, tornando-o uma escolha preferida para marcas focadas em jeans tradicionais e premium.

O processo de tingimento de corda

O tingimento de corda é uma técnica tradicional de tingimento de fios que enfatiza a profundidade, textura, e cor duradoura. O processo envolve várias etapas precisas:

- Preparação de Fios: Os fios de algodão são primeiro fiados e depois torcidos em cordas grossas. Esta torção permite a absorção uniforme do corante e facilita o manuseio durante vários banhos de corante.

- Mergulho Inicial: Os fios são imersos em uma cuba de corante índigo. Apenas a superfície absorve a cor no início, enquanto o núcleo permanece mais leve.

- Oxidação: Depois de cada mergulho, os fios são expostos ao ar para oxidar o índigo. Esta etapa escurece o fio gradativamente e garante um desenvolvimento consistente da cor.

- Mergulho repetido: As cordas são repetidamente mergulhadas e oxidadas. Jeans de alta qualidade podem exigir 8 para 12 mergulha para alcançar o azul profundo desejado.

- Enxaguar e amaciar: Após o mergulho final, os fios são completamente enxaguados para remover o excesso de tinta e tratados com agentes amaciantes para melhorar a sensação ao toque.

- Secagem e Armazenamento: As cordas tingidas são cuidadosamente secas, verificado quanto à uniformidade, e armazenados até que estejam prontos para tecer.

Prós e contras do tingimento de corda em jeans

Prós:

- Profundo, cor rica: O índigo penetra nos fios gradativamente, criando profundidade única.

- Desbotamentos duradouros: O diferencial na penetração da tinta garante um lindo desbotamento natural ao longo do tempo.

- Textura premium: Os fios mantêm uma forte, sensação suave da mão, fazendo o tecido jeans mais confortável.

- Personalização: Mais fácil de controlar para efeitos especiais, como fios soltos ou tingimento irregular para um visual vintage.

Contras:

- Alto custo: Tingimento de corda requer mais mão de obra, água, e tempo.

- Produção mais lenta: Vários mergulhos e períodos de oxidação podem levar vários dias.

- Impacto ambiental: Maior uso de água e mais desperdício de corante em comparação com o tingimento slasher.

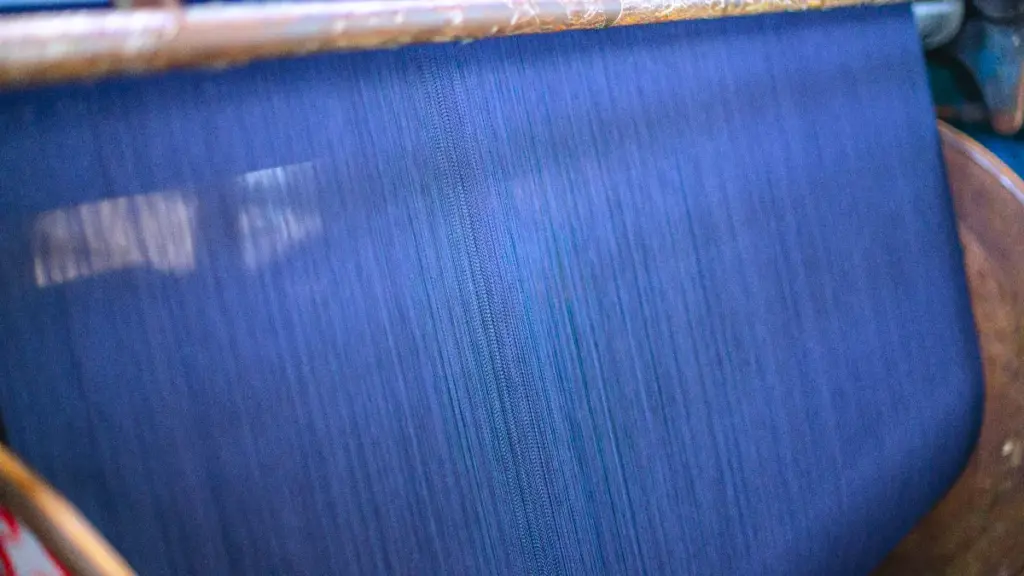

O que é tingimento Slasher?

Tingimento slasher, também chamado de tingimento de folha ou urdidura, é um moderno, método eficiente para colorir fios de jeans. Os fios são alinhados e passados por banhos de corante índigo em folhas contínuas. A tinta cobre principalmente a superfície, deixando o núcleo interno mais leve. Este método produz uniforme, cor consistente e é mais rápido e econômico do que o tingimento de corda. Embora crie jeans adequados para produção em massa, o tecido resultante geralmente tem uma sensação um pouco mais rígida e desbotamento com menos nuances em comparação com o jeans tingido com corda.

O processo de tingimento Slasher

O tingimento Slasher é mais rápido, método eficiente de tingimento de fios amplamente utilizado na produção industrial de denim. Seu fluxo de trabalho é estruturado e contínuo:

- Alinhamento de Fios: Os fios da urdidura são espalhados e alinhados em forma de folha. Este arranjo garante que cada fio receba exposição consistente ao corante.

- Aplicação de corante: A folha de fios passa por uma série de banhos de corante índigo. Cada banho deposita cor principalmente na superfície do fio, deixando o núcleo um pouco mais leve.

- Oxidação: Após cada banho de tingimento, os fios são expostos ao ar para oxidação. Ao contrário do tingimento de corda, o arranjo plano acelera esse processo.

- Múltiplas passagens: A folha do fio passa por vários banhos dependendo da profundidade de cor desejada. Geralmente, são necessárias menos passagens do que o tingimento de corda para tons semelhantes.

- Lavagem: O excesso de índigo é removido através de enxágue controlado para evitar manchas irregulares e manter a consistência do tecido.

- Secagem e Bobinagem: Os fios tingidos são secos sob tensão e enrolados em feixes, pronto para tecelagem ou processamento posterior.

Prós e contras do tingimento Slasher

Prós:

- Econômico: Usa menos água e corante, reduzindo custos de produção.

- Mais rápido: As folhas de fios passam por vários banhos de tingimento em um ciclo contínuo.

- Consistente: O processo garante cor uniforme em lotes grandes.

- Mais ecológico: Menos consumo de água e redução de resíduos químicos.

Contras:

- Profundidade de cor rasa: O corante penetra apenas na camada externa, levando a um desbotamento mais rápido.

- Menos variedade de texturas: Capacidade limitada de criar manchas ou efeitos de tingimento irregulares.

- Sensação de mão mais rígida: O fio é um pouco menos macio em comparação com o jeans tingido com corda.

Denim personalizado sob medida para a visão da sua marca

Faça parceria com a Changhong para criar estilos exclusivos de jeans com tamanhos de pedido flexíveis, tecidos sustentáveis, e artesanato especializado. Do tecido ao acabamento, dê vida às suas ideias de jeans personalizados com precisão e cuidado.

Qual método de tingimento combina com você?

A escolha entre tingimento de corda e slasher depende de prioridades:

- Amantes de jeans premium: O tingimento de corda oferece profundidade incomparável, textura, e desaparecendo. É ideal para clientes que apreciam o artesanato tradicional e a forma como o jeans evolui com o uso.

- Marcas do mercado de massa ou fast fashion: O tingimento Slasher proporciona eficiência, relação custo-benefício, e benefícios ambientais. É perfeito para pedidos de alto volume sem comprometer a qualidade básica.

Perguntas frequentes sobre tingimento índigo

Quais são os tipos de tingimento têxtil?

O tingimento têxtil inclui o tingimento de fios, pedaço (tecido) tingimento, e tingimento de roupas. Tingimento de fios, como tingimento de corda e slasher, colore os fios antes de tecer, oferecendo mais controle sobre a profundidade da cor. O tingimento de tecidos e roupas ocorre após a tecelagem ou costura, que é mais rápido, mas menos durável.

Que tipo de tecido é melhor para tingir?

Algodão domina jeans produção porque absorve bem o índigo, é durável, e suaviza com o tempo. Algumas misturas, como algodão-poliéster, pode ser tingido, mas não pode desbotar naturalmente, o que é crucial para a estética do jeans premium.

Qual é a diferença entre índigo natural e sintético?

O índigo natural vem da planta Indigofera e tem variações sutis de cores. O índigo sintético é produzido quimicamente, mais consistente, e amplamente utilizado na produção industrial de denim. O jeans mais moderno, incluindo corda e tecidos tingidos com slasher, usa índigo sintético devido ao custo e escalabilidade.

Por que o índigo desaparece no jeans com o tempo?

A tintura índigo fica principalmente na superfície dos fios. À medida que o tecido sofre fricção e lavagem, a tinta da superfície desaparece gradualmente, revelando camadas mais claras por baixo. Jeans tingidos com corda mostram-se mais lentos, desbotamento mais texturizado, enquanto slasher-tingido jeans desbota mais uniformemente.

Como os métodos de tingimento afetam a aparência final do jeans?

O tingimento de corda produz um resultado mais rico, aparência mais texturizada com fades e slubs diferenciados. O tingimento Slasher proporciona uma cor uniforme, desbotamento consistente, e menos variação na textura. O método escolhido molda as qualidades estéticas e táteis do jeans.

Qual método de tingimento é mais sustentável?

O tingimento slasher é geralmente mais ecológico porque usa menos água, produtos químicos, e energia. O tingimento de cordas consome mais recursos, mas pode ser otimizado com processos modernos de gestão e reciclagem de águas residuais. A sustentabilidade depende tanto das práticas de produção quanto da escolha do tingimento.