ほぼ毎日履いていますね, でも、あなたのジーンズに実際何が入っているのか調べたことはありますか??

ほとんどの人は単純に答えますが、 “コットン,” 現実はもう少し技術的です. デニムは、特定の繊維のブレンドによって定義される複雑な生地です, 正確な糸の撚り, ユニークな織り構造により、入手可能な繊維の中で最も耐久性のある生地の 1 つとなります。.

あなたがデニム愛好家で、生デニムがなぜあんなに硬いのかを理解しようとしている人も, または次のコレクションの素材を調達したいファッション ブランド, 構成を理解することが重要です. このガイドでは、デニムが何から作られているかを正確に説明します。, 原料の繊維から完成した生地まで.

デニムを定義する核となる成分

歴史的に, デニムは単一の材料によって定義されました: 100% コットン. しかし, 生地が大幅に進化しました. 今日, ほとんどのデニムは、過去の頑丈な感触と現代の消費者が求める快適さのバランスを取るように設計された複合素材です.

ファンデーションはほとんどコットンです, 自然な引張強度と通気性のために選ばれました。. しかし、パフォーマンスを向上させるためには, 現代の工場では綿と合成繊維を頻繁に混紡しています.

- エラスタン (スパンデックス): ストレッチと回復のために追加.

- ポリエステル: 耐久性を高め、収縮を制御するために添加.

ブレンドに関わらず, 品質は繊維の長さから始まります. メーカーは長繊維綿を好む, リングスパン糸に紡がれることが多い, 繊維が長いほど表面が滑らかになるため. これにより、生地は染料をよりよく保持し、時間が経つにつれて自然に柔らかくなります。, 壊れるのではなく.

特徴的な斜めの織りパターン

ツイル織りがどのように外観を作り出すのか

シンプルな市松模様の平織りとは一線を画す, デニムはツイル織りを使用して設計されています. これはデニムと標準的なキャンバスを区別する技術的特徴です.

この構造は、垂直の経糸と水平の緯糸の相互作用に依存しています。. クラシックで 3/1 ツイル構造, 青い縦糸が3本の白い横糸を越えてから1本の下を通過します。. この高密度の糸により、生地は標準的な綿織りよりも大幅に重くなり、耐摩耗性が高くなります。.

なぜ内側は白く外側は青いのか

青い顔と白い背中の特徴的なコントラストは、 3/1 織り構造.

青い縦糸が複数の横糸を交差させているため、, それらは表面を支配します デニム生地. その間, 染まっていないもの, 自然な白い横糸はほとんど裏側に残ります. ジーンズの裾を閉めると、コントラストのある白い内側が現れるのはこのためです.

左綾織りと右綾織りの比較

織り方向が生地の柔らかさと色褪せの特性を決定します.

- 右綾織り (RHT): Levi's などのブランドが使用する業界標準. 線は右斜め上に伸びています. これにより、より耐久性と耐摩耗性が向上したより緊密な構造が形成されます。.

- レフトハンドツイル (LHT): 線路は左に上がっていきます. 糸の自然な撚りに逆らって織ることにより、, LHT は、手触りが大幅に柔らかくなり、垂直方向に色褪せる生地を作成します。, 時間の経過とともに現れる縞模様の美しさ.

超えて 100% コットン: モダンなマテリアルブレンド

伝統主義者は純綿を好む, しかし、今日のほとんどの消費者は、実際に着られるジーンズを望んでいます. 工場は、特定の繊維ブレンドを設計することでこの柔軟性を実現しています。.

伸縮性のためにエラスタンが添加される理由

動きを妨げず、体にフィットするジーンズを作るために, メーカーは綿と合成エラストマーをブレンドしています.

メーカーは通常、1 ~ 5% のエラスタンを追加します。, スパンデックスやライクラなど. 最高のストレッチデニムを使用 “コアスピニング” テクノロジー, 伸縮性のあるスパンデックスフィラメントが、包まれた綿の外側層の中に隠されています。. デニムの本格的な見た目とアクティブウェアの快適さを提供します。.

強度と耐久性を高めるポリエステルブレンド

ポリエステルを添加することで耐久性が向上する場合が多い. 作業着や摩擦の多いデニムで, ~の範囲のポリエステル加工糸 300 に 600 よこ糸にデニールが使用されています.

プレミアムセグメントでは, T400 のような高度なポリエステル (エラストマルチエステル) 形状保持性を向上させるために使用されます, ジーンズの発生を防ぐ “袋詰めする” 繰り返し着用後の膝部分.

知っておくべき一般的な生地の比率

デニムを調達または購入するとき, これらの比率はラベルによく表示されます:

- 100% コットン: 硬い, 本物, ゼロストレッチ.

- 98% コットン / 2% エラスタン: の業界標準 “快適なストレッチ。”

- 70% コットン / 28% ポリエステル / 2% エラスタン: 共通の “トライブレンド” 高い耐久性と形状保持性を実現するように設計されています.

ビジョンを解き放つ: プレミアムカスタムデニム, コンセプトからコレクションまで.

デニムがその象徴的な青色になるまで

デニムの独特な色落ち特性は、インディゴ染料の特定の化学的挙動に由来します。. 繊維に完全に浸透する標準的なガーメントダイとは異なります。, インディゴは動作が異なります.

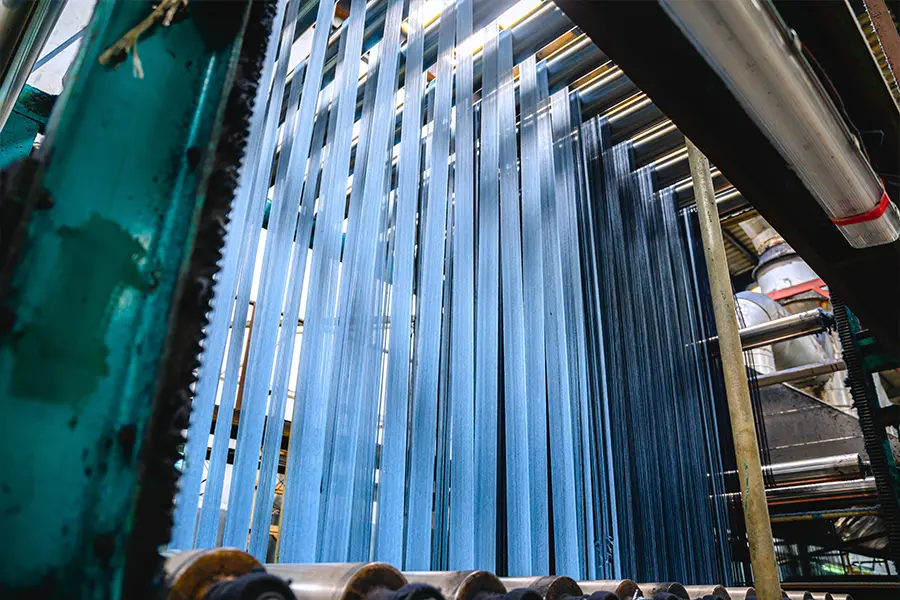

の “リング染色” プロセス

ジーンズが青いのはリング染色と呼ばれる工程によるものです. インディゴの分子は大きすぎるため、綿糸の芯に簡単に浸透できません。. 隅々まで浸かるのではなく、, 染料は糸の表層にのみ存在します, 皮膚のように. 糸の中心は白いまま. この物理的構造は、デニムの独特の色落ち特性の前提条件です。.

天然インディゴと合成インディゴの違い

染色のメカニズムは同じですが、, 商業生産では染料の供給源が大きく異なります.

- 天然藍: から抜粋 インディゴフェラ 植物. 高価です, 労働集約的な, そしてユニークなものを生み出します, バッチごとに異なるわずかに緑がかった青の色合い.

- 合成インディゴ: で使用されます 99% モダンなジーンズの. 純粋な, 深いブルーのトーンで一貫性を実現, スケーラブルな生産.

ジーンズを履いていると, 染料がゆっくりと表面をこすっていきます, その下の白い綿の芯が現れる. この染料の機械的損失により、 “色褪せる” または “ひげ。”

ブラックデニムとカラーデニムの硫化染め

ブラックジーンズには硫化染料が使われていることが多い. インディゴと違って, 硫化染料は繊維と異なる結合をします。. 色を保持するように設計されたものもあります, として知られている “ステイブラック” テクノロジー, 他のものは洗い流すと灰色になるように設計されています, 伝統的なブルーデニムの経年変化を模倣.

厚手の生地と軽量の生地のオプション

デニムは重さによって厳密に分類されます, オンス/平方ヤードで測定される (オズ). これにより、生地の耐久性と季節への適合性が決まります。.

軽量デニムを選択する場合

軽量デニムの計量 10.5 サマーコレクションや体に沿って動く必要がある衣類には、オンス以下が最適です。, ドレスやワイドパンツなど.

着ていて涼しいだけではありません, 軽量の生地は、厚手のツイルでは実現できない滑らかなドレープを実現します。. 生産ラインから出た直後は柔らかいです, すぐに快適さを提供. 大衆市場や湿気の多い気候をターゲットとするブランド向け, これにより、 “押し入る” 多くの場合、平均的な消費者の行動を妨げる障壁.

ヘビーウェイト生デニムの利点

伝統的なブランドとデニムの純粋主義者向け, 上は厚手の生地 16 オンスはゴールドスタンダードです.

その主な利点は構造記憶です。. 生地がしっかりしているので型崩れしにくいです, シャープな作成, 膝の後ろと腰に永久的なしわがある. 時間とともに, これにより、明るい生地では決して生成できない、濃い青と深い白を特徴とするハイコントラストの色落ちが得られます。. 侵入するには忍耐が必要ですが、, その代わりに、実質的に壊れにくく、着用者に合わせて高度にパーソナライズされた衣服が得られます。.

デニムの重量の簡単な比較

| カテゴリ | 体重範囲 | 季節性 | 慣らし期間 | 最優秀アプリケーション |

|---|---|---|---|---|

| 軽量 | 4 – 10.5 オズ | 春 / 夏 | なし. 柔らかくて履き心地がよく、届いてすぐに使えます. | デニムシャツ, サマードレス, ワイドレッグパンツ. |

| 中量級 | 11 – 15.5 オズ | オールシーズン (一年中) | 最小限. 柔らかくなり体にフィットするには、3 ~ 5 回の着用が必要です. | ジーンズの古典的なスタンダード (例えば, リーバイス501), デニムジャケット. |

| ヘビー級 | 16 – 32 オズ | 秋 / 冬 | 重要な. 完全になじむまでには数週間または数か月かかる場合があります. | 伝統的なワークウェア, オートバイギア, ハイコントラストのフェードプロジェクト. |

持続可能で環境に優しい生地の選択

デニム業界は環境への影響を削減する必要に迫られています. 現代の構成は責任ある調達へと移行しています.

オーガニックコットンとリサイクル繊維

持続可能な素材の採用は、ほとんどの現代ブランドにとって優先事項です. しかし, 工場の床で, この決定により、繊維の長さと引張強度に関する特定の技術的課題が生じます。.

- オーガニックコットン (GOTS/OCS認証済み): 物理的に, オーガニックコットン 従来のコットンと同様の性能を発揮します, しかし、GMO種子や合成農薬を使わずに栽培されています。. メーカー向け, 主な違いは認定証跡にあります. 高品質のオーガニックデニムは、二次汚染を防ぐために工場内で厳密に分離する必要があります, 最終的な生地が世界的なオーガニックテキスタイル基準を満たしていることを確認する (ゴッツ) 要件.

- リサイクルコットン (の “短繊維” チャレンジ): ここでエンジニアリングが重要になります. メカニカルリサイクルでは古い生地を細断します。, 必然的に綿の繊維が切れてしまいます, バージン繊維よりも大幅に短く、弱いものになります。.

技術的な意味: 生地の引き裂き強度を維持するため, リサイクル繊維と長繊維バージンコットンまたは合成補強材をブレンドする必要があります. その結果, ジーンズの耐久性を確保するために、通常はリサイクル含有量を 20 ~ 40% に制限します。.

現代の代替品としてのテンセルとヘンプ

テンセルのような繊維を見かけることが増えてきました。 (リヨセル) またはヘンプをデニムにブレンド. 環境に優しいという評判を超えて, これらの繊維は、生地の手触りを変える明確な物理的利点を提供します。.

- テンセル (リヨセル): 木材パルプ由来, テンセルはその極めて滑らかな表面構造で高く評価されています。. コットンと混紡すると, 従来のデニムよりも大幅に柔らかく、流動性のある生地を作成します。 “ドレープ。” そのため、快適さが最優先される軽量のサマージーンズやレディースファッションに理想的な選択肢となります。.

- 麻: 麻は地球上で最も強い天然繊維の一つです, 綿に匹敵する、あるいは綿を超える耐久性を実現. 歴史的には荒っぽいながらも, モダンな “綿化” 加工により繊維が柔らかくなり、綿とほとんど区別がつかないほどの感触になります。. 栽培に必要な水と農薬ははるかに少ない, ジーンズの頑丈な丈夫さを犠牲にすることなく、持続可能なプロファイルを提供します。.

品質は生地から始まります

生地の選択が間違っていても、縫製を良くしても直すことはできません. デニム製品の成功は、ほぼ完全に最初の原材料にかかっています。.

あなたが消費者の場合, 成分表示をチェックすれば、安価な合成繊維に割高な価格を支払っていないことを確認できます. あなたがブランドなら, 精度は顧客ロイヤルティの基礎です. 12オンスのコンフォートストレッチが必要な場合でも、16オンスのリジッドツイルが必要な場合でも, 正確に適切な材料を選択することが、顧客が再び購入する製品を構築する唯一の方法です.

このため、材料科学を真に理解している製造パートナーを選択することが重要です. で チャンゴン, ジーンズを縫うことは仕事の半分にすぎません. エンドツーエンドで提供します 衣料品製造ソリューション 物質的な専門知識に根ざした. 生地組成に関する深い知識を活用して、デザインが必要とする正確なデニムブレンドを調達します。, すべてのジャケットを確実に, ジャン, 当社が製造するスカートは耐久性とフィット感の最高基準を満たしています。.

デニムの魂を理解するメーカーを探しています? 今すぐお問い合わせください カスタムジーンズの生産を始めるには.

よくある質問

違いは何ですか デニムとシャンブレー?

主な違いは織り構造にあります. デニムは斜めの綾織りを使用しています, そのため重くて耐久性があります. シャンブレーはシンプルな平織りを使用, これにより、シャツに適した軽量で通気性の高い生地が生まれますが、ジーンズに必要な丈夫さはありません。.

する ストレッチデニム よりも早く消耗する 100% コットン?

はい. コットンは驚くほど耐久性がありますが、, エラスタン繊維は熱と摩擦により早く劣化します. この劣化により、最終的には生地が回復力を失い、膝や腰の部分が袋状になってしまいます。. ヘビー級のペア 100% コットンジーンズは何十年も履ける, 一方、ストレッチデニムは通常、最適な形状を維持します。 2 に 5 年.

どういうことですか “サンフォライズされた” デニム生地の意味?

サンフォライズドとは、工場で行われる機械的な事前収縮プロセスを指します。. 最大まで縮む可能性がある非防腐処理生地やシュリンクトゥフィット生地とは異なります。 10% 洗濯後, サンフォライズドデニムは、縮みが少なくなるように安定化されています。 1%. これにより、製造するサイズが最終消費者にとって一貫したものとなることが保証されます。.

する “耳” デニム より高品質の素材を暗示します?

必ずしもではありません. セルビッジとは、綿そのものの品質ではなく、ヴィンテージのシャトル織機で作られた自己仕上げされた端のみを指します。. メーカーは技術的にはこれらの織機で低品質の糸を織ることができます. したがって、購入者はエッジの仕上げだけよりもステープルの長さなどのファイバーの仕様を優先する必要があります。.

何が生み出すのか “結婚式” いくつかのデニム生地のテクスチャー?

意図的に太さを不均一にして紡績した糸を使用することで生まれるスラブ質感. これらの可変セクションは、触覚的で凹凸のある表面構造を作成します。. この不規則性は、その独特の縦方向の色落ちの特徴とヴィンテージの美しさから、プレミアムデニムで高く評価されています。.