You have decided to move away from conventional denim. Now comes the harder choice: should you build your new line with organic cotton or hemp?

Both reduce environmental impact compared to standard denim. Cependant, they differ significantly in cost, texture, and how they behave during production. This guide compares these materials to help you make the right sourcing decision.

Why the Market is Shifting to Sustainable Denim Fabrics

Conventional denim production presents significant environmental challenges. It requires excessive water and heavy chemical use. Industry assessments indicate that producing a single pair of jeans consumes thousands of liters of water and generates significant CO₂ emissions.

Consumer Demand for Eco-Friendly Jeans and Jackets

Shoppers today prioritize transparency regarding fiber origins and production methods. Brands that can verify their claims are building stronger trust and market position. Certifications like GOTS (Norme mondiale sur les textiles biologiques) or OCS (Organic Content Standard) serve as powerful tools to validate this commitment.

The Problem with Conventional Cotton in Garment Production

Cotton farming is a major consumer of water in the denim supply chain. En plus, the runoff from traditional indigo dyeing often negatively impacts local water systems. For brands aiming to meet sustainability goals like SDG 6, replacing conventional cotton is the most impactful operational change.

Organic Cotton vs. Hemp: Which Has a Lower Environmental Impact?

Both materials are eco-friendly, but they address environmental concerns in different ways.

Water Usage and Pesticide Reduction in Organic Cotton

Organic cotton farming prohibits synthetic pesticides. This protects soil health and local water systems. When factories process this cotton using modern technologies like ozone fading, they can drastically reduce water usage in the laundry stage compared to traditional methods.

The Carbon Footprint and Soil Benefits of Growing Hemp

Hemp acts as a highly effective carbon sink. It grows rapidly, requires minimal water, and is naturally resistant to pests. This often eliminates the need for agrochemicals entirely. If your brand’s value proposition focuses on carbon reduction or regenerative agriculture, hemp is the ideal material choice.

Comparing Durability and Fabric Texture

Sustainability drives the initial purchase, but comfort ensures customer retention. Here is how these materials perform in the final garment.

The Softness and Breathability of Organic Cotton

Organic cotton offers a soft, familiar hand-feel immediately off the rack. It is naturally breathable and requires no “break-in” period. If you are designing for comfort or a vintage aesthetic, organic cotton is the market-standard choice.

Why Hemp Denim is Known for Exceptional Strength and Longevity

Hemp fibers are inherently strong. Denim blended with hemp has higher tensile strength, making it suitable for workwear-inspired lines. While 100% hemp can feel rigid initially, hemp/cotton blends soften beautifully with wear. They also offer a unique, irregular texture (often called “mariage”) that is highly valued in the premium denim market.

Unlock Premium Custom Denim for Your Brand

Technical Challenges in Manufacturing Sustainable Denim

Hemp and organic cotton behave differently from standard tissu en jean during sewing. Without precise handling, production issues such as seam twisting or dimensional instability can occur.

Managing Shrinkage and Texture in Hemp Denim Manufacturing

Hemp has different shrinkage rates compared to cotton. If the sanforization process is not accurately calibrated, le jeans may warp after the first home wash. Experienced manufacturers use specific enzymatic treatments and tension controls to stabilize hemp blends. This ensures the fit remains consistent.

Expertise Required for Cutting and Stitching Heavyweight Eco-Denim

Processing heavyweight eco-denim (13 onces+) requires specialized equipment. The dense fibers of hemp blends can cause needle breakage or uneven stitching on standard machines. Your factory must utilize heavy-duty equipment and skilled operators. This ensures the construction is as durable as the fabric itself.

Hemp vs. Coton biologique: Which Costs More?

Why Hemp Often Commands a Higher Premium than Cotton

Currently, hemp denim has a higher production cost. The global supply chain for fine hemp yarn is smaller and more complex than cotton’s. Organic cotton is also priced higher than conventional cotton. Cependant, it benefits from a more established infrastructure, making it a more cost-effective, sustainable option.

Calculating the Long-Term ROI for Your Sustainable Brand

The higher cost of hemp allows for premium market positioning. You can justify a higher retail price by marketing the product’s superior durability and environmental benefits. Organic cotton is the practical choice for accessible, mid-range collections.

When to Choose Hemp vs. Coton biologique

Use this comparison matrix to determine the best fit for your specific product line:

| Fonctionnalité | Coton biologique | Hemp (or Hemp Blends) |

|---|---|---|

| Texture & Sensation de main | Doux, lisse, and familiar immediately off the rack. | Initially rigid but softens with wear. Unique “mariage” texture. |

| Durabilité | Standard denim durability. | Exceptional tensile strength. Highly resistant to abrasion. |

| Cost Profile | Mid-range. More accessible for volume production. | Prime. Higher material cost due to complex processing. |

| Sustainability Focus | Reduced water usage and zero synthetic pesticides. | High carbon sequestration and soil regeneration. |

| Best End-Use | Jean skinny, comfort stretch, and classic vintage styles. | Vêtements de travail, heritage rigid denim, and luxury collections. |

Taking the Next Step with a Trusted Manufacturing Partner

You have the vision and the materials in mind. Maintenant, you need a factory that can accurately manage shrinkage rates and compliance documentation.

Changhong provides integrated denim manufacturing solutions, taking you from concept to shelf with a strict focus on sustainability:

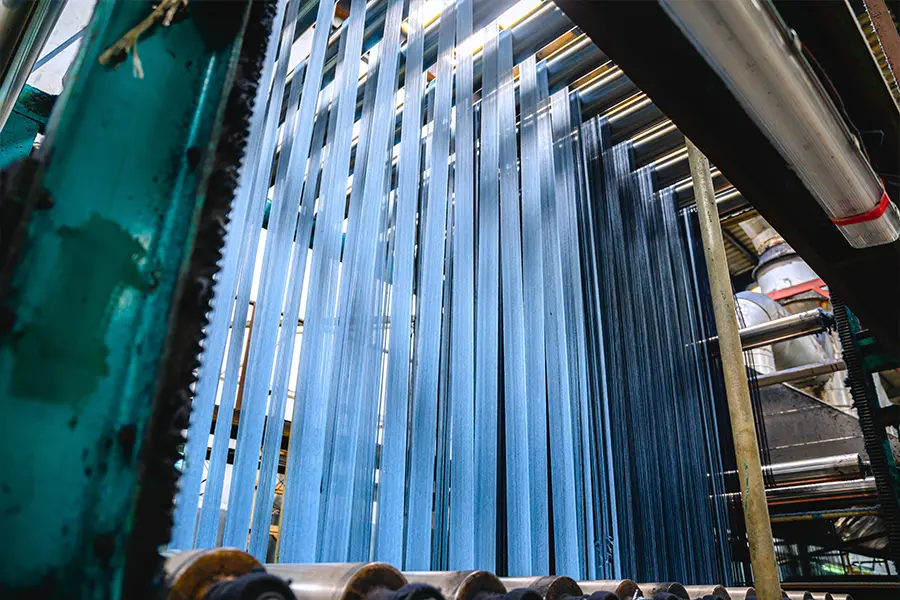

- Eco-Conscious Production: We utilize advanced eco-dyeing technologies and water-saving finishing processes to minimize the environmental footprint of every pair of jeans we manufacture.

- Sustainable Material Sourcing: Beyond just processing, we actively source and utilize certified organic cotton, recycled materials, and premium hemp blends to meet your specific eco-targets.

- Green Design & Développement: Our design team specializes in sustainable product development, helping you create durable, circular denim products that align with modern eco-standards.

- Socle & ODM Services: Whether you need full design assistance or production based on your tech packs, we adapt to your needs.

- Verified Compliance: We hold ISO9001 and BSCI certifications. We also manage the chain of custody for organic and recycled materials.

Ready to start your sustainable denim line? Contact us today to discuss your project.

FAQ

What is the typical lead time for sustainable denim production?

Lead times depend on fabric stock levels. Generally, bulk production takes 30–50 days after sample approval. Changhong works to optimize this timeline to help you meet your market launch dates.

Can I add sustainable stretch (Élasthanne) to hemp or organic cotton jeans?

Oui. We often blend hemp or organic cotton with 1–3% recycled elastane or recycled polyester (rPET). This ensures the garment has the stretch and comfort consumers expect, without compromising its eco-credentials.

Do you offer sampling services before full bulk production?

Oui. We view sampling as a critical step. Prototyping allows you to verify the fit, wash effects, and hand-feel before committing to a full production run.

What is the MOQ (Quantité minimum de commande) for custom eco-jeans?

We support emerging brands. While MOQs vary based on fabric choice and wash complexity, we offer flexible minimums to make launching new sustainable lines viable.

Can I customize the specific blend percentage of hemp and cotton?

Oui. We can manufacture garments based on your specific requirements. Par exemple, we can create a 55% chanvre / 45% organic cotton blend to achieve the exact balance of cost and texture you need.