Warum behalten manche Jeans den ganzen Tag ihre Form, während andere schon mittags kaputt gehen?? Das Geheimnis liegt im Gewebe. Ganz gleich, ob Sie auf der Suche nach Ihrem nächsten Bestseller sind oder auf der Suche nach der perfekten Lösung sind, Die Wahl zwischen 2-Wege- und 4-Wege-Stretch wirkt sich direkt auf Ihre Produktionskosten und die Kundenzufriedenheit aus. Von der Verbrauchsrate bis zur Verwertungsleistung, Hier finden Sie den technischen Leitfaden für die richtige Investition.

Was sind 4-Wege- und 2-Wege-Stretch-Denim??

Bevor Sie sich mit der Preisgestaltung oder Beschaffung befassen, Sie müssen die mechanischen Unterschiede in der Konstruktion dieser Stoffe verstehen.

2-Wegstrecke: Der Industriestandard (Nur Schuss)

2-Way-Stretch-Denim ist so konstruiert, dass es sich nur in eine Richtung dehnt: fast immer horizontal über den Schuss. Dies ist der Standard für die meisten kommerziellen Jeans. Es sorgt für das Notwendige “geben” für Komfort im Hüft- und Oberschenkelbereich und gleichzeitig vollständige Stabilität in vertikaler Richtung.

4-Wegstrecke: Hochleistungsentwicklung (360° Bewegung)

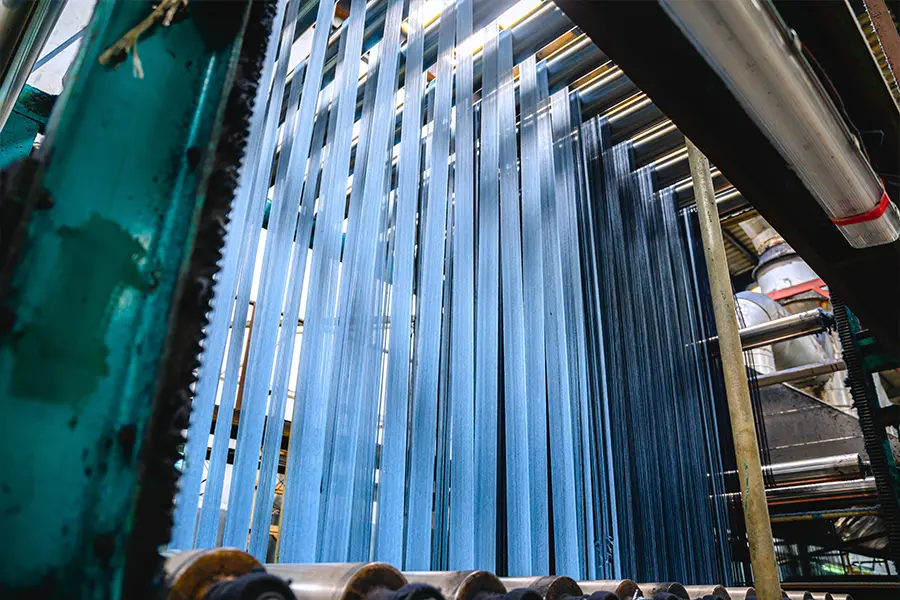

4-Way Stretch Denim ist ein Hochleistungsstoff, bei dem elastische Garne in beide Ketten eingewebt sind (Vertikale) und Schuss (horizontal) Wegbeschreibungen.

Herkömmlicher Denim fühlt sich oft steif an. 4-Way Stretch ändert dies, indem es Flexibilität direkt in die gesamte Struktur des Stoffes einbaut. Dadurch kann sich das Material ausdehnen und zusammenziehen, runter, und Seite an Seite, Schaffung echter 360°-Mobilität.

Die Mechanik: Warp vs. Schusskonstruktion

- Der 2-Wege-Mechanismus: Das elastische Filament (Spandex/Elastan) wird nur in die Schussfäden eingefügt. Die vertikalen Kettfäden bleiben aus starrer Baumwolle, um sicherzustellen, dass die Schrittlänge stabil bleibt.

- Der 4-Wege-Mechanismus: Auch in den vertikalen Kettfäden ist Elastizität integriert. Dadurch kann sich der Stoff mit der Bewegung des Körpers ausdehnen (als würde man ein Knie beugen) ohne den Saum hochzuziehen oder Spannungspunkte zu erzeugen.

Hauptunterschiede: 2-Weg vs. 4-Way-Stretch-Leistung

Als Käufer, Ihre Wahl zwischen diesen beiden Stoffen bestimmt die endgültige Passform und das Kundenerlebnis.

Vergleich von Elastizität und Bewegungsumfang

- 2-Weg: Angebote “Komfort-Stretch.” Es ist zuverlässig und spezifisch. Es ermöglicht eine Erweiterung bei Bedarf (Taille/Gesäß) behält aber die Kernstruktur des Kleidungsstücks bei.

- 4-Weg: Liefert “Aktive Dehnung.” Es bietet eine körpernahe Passform, die sich mit dem Träger bewegt, ohne ihn einzuengen, Wir schließen die Lücke zwischen klassischem Denim und Activewear.

Formerhaltung und Wiederherstellung

Die Formbeständigkeit ist ein Hauptanliegen der Verbraucher.

- 2-Wegerisiken: Kann dazu neigen “auspacken” an stark beanspruchten Stellen wie den Knien nach längerem Tragen bei geringer Elastanqualität.

- 4-Weglösungen: Verwendet in der Regel fortschrittliche Wiederherstellungstechnologie. Denn der Stoff kann aus allen Richtungen zurückschnellen, es widersteht dem Durchhängen viel effektiver. Jedoch, Dies erfordert eine präzise Stoffauswahl, um sicherzustellen, dass die Fabriken das Material ordnungsgemäß thermofixiert haben.

Körperformung: Was eine bessere Passform bietet?

- 2-Weg: Am besten für strukturierte Silhouetten (Gerades Bein, Bootcut) Das Ziel besteht darin, dass sich der Stoff am Körper anschmiegt und nicht an jeder Rundung anliegt.

- 4-Weg: Ideal für “Körpernah” passt (Schlank, Jeggings). Es passt sich Änderungen des Körpervolumens und verschiedenen Körperformen toleranter an als 2-Wege-Stoff.

Schwindung & Stabilität: Vertikal vs. Horizontal

Dies ist ein kritisches Produktionsdetail, das bei der Beschaffung oft übersehen wird.

- 2-Weg: Stabil in Längsrichtung. Jedoch, Traditionelle Köperbindungen sind von Natur aus anfällig dafür “Beindrehung” (verzerrt) nach dem Waschen, wenn der Stoff in der Fabrik nicht richtig schief war.

- 4-Weg: Weil die vertikale Kette elastisch ist, Die vertikale Schrumpfung ist das Hauptanliegen. Muster müssen angepasst werden, um hohen Schrumpfraten Rechnung zu tragen (erfordert oft negative Leichtigkeit) um zu verhindern, dass das fertige Kleidungsstück danach zu kurz oder zu eng wird Jeanswäsche.

Vom Konzept zur Kollektion: Ihr erfahrener Denim-Herstellungspartner

Was sie unterscheidet?

Standardkompositionen: Baumwoll-Poly-Spandex-Mischungen (2-Weg)

Die klassische Formel für 2-Wege-Stretch lautet oft a “98/2” Mischung (98% Baumwolle, 2% Elasthan).

Jedoch, eine kommerziellere Mischung für den Massenmarkt sieht oft so aus:

- 75% Baumwolle / 23% Polyester / 2% Elasthan.

Dieses Trio bietet die Haptik von Baumwolle, die Haltbarkeit von Polyester, und die nötige Flexibilität von Spandex.

Fortschrittliche Technologie: Dual-Core & Multidirektionale Garne (4-Weg)

4-Way-Stretch erfordert eine ausgefeiltere Technik, um zu verhindern, dass der schwere Stoff unter seinem Eigengewicht durchhängt.

- Dual-Core-Technologie: Dabei wird eine Baumwollhülle um zwei innere Filamente gewickelt: eine Elastanfaser für sofortige Dehnbarkeit, und ein stärkeres Filament (wie LYCRA® T400®) für Erholung und Kraft.

- Kerngesponnene Garne: Unverzichtbar zum Schutz des empfindlichen Elasthans im Inneren einer Baumwollhülle, das Authentische bewahren “Denim-Look” trotz des hohen synthetischen Anteils.

Der Einfluss des Elastananteils auf Gewicht und Griffgefühl

Entgegen der landläufigen Meinung, Ein höherer Spandex-Anteil bedeutet nicht immer eine bessere Leistung.

- 1% Elasthan: Bietet einen starren Look mit leichtem Komfort.

- 1–4 % Elastan: Der Sweet Spot für Hochleistungs-Stretch. Auch in technischen Geweben, Der endgültige Elastangehalt bleibt in der Regel niedrig (Z.B., 1.78% Zu 2.03%) um ein synthetisches zu vermeiden, “gummiartig” Handgefühl.

Welchen Denim-Stoff sollten Sie wählen??

Persönliche Vorlieben sollten diese Entscheidung nicht beeinflussen. Stattdessen, Sie müssen die ausrichten Denim-Stoff Leistung direkt mit Ihrer Produktlinie und Ihrer Zielgruppe.

In der folgenden Tabelle sind die idealen Anwendungen für jeden Stofftyp aufgeführt, um Ihnen dabei zu helfen, Ihre Materialbeschaffung an Ihre Designabsicht anzupassen.

Schneller Vergleich: Beste Anwendungsfälle

| Anwendungsfaktor | 2-Wegstrecke (Der Industriestandard) |

4-Wegstrecke (Die Leistungswahl) |

|---|---|---|

| Ideale Passform | Gerade, Bootcut, Normale Passform. Am besten geeignet für Schnitte, die fallen und eine vertikale Linie halten müssen, ohne zu kleben. | Schlank, Superdünn, Jeggings. Unverzichtbar für “zweite Haut” Passformen, die sich jeder Kurve anpassen müssen. |

| Zielgruppe | Männermarkt & Heritage-Linien. Verbraucher, die das wollen “sehen” aus festem Denim, brauchen aber versteckten Komfort. | Frauenmarkt & Aktiver Lebensstil. Verbraucher legen Wert auf Shapewear-Effekte (“Bildhauerei”) oder hohe Mobilität. |

| Bekleidungsarten | Klassische 5-Pocket-Jeans, Jeansjacken, Overall, Von Arbeitskleidung inspirierte Stücke. | Yoga-Jeans, Pendler-Rad-Denim, High-Fashion-Bodys, Umstandsjeans. |

| Ästhetisches Ziel | “Authentischer Denim.” Behält den traditionellen Slub-Charakter und den robusten Look von Vintage-Jeans bei. | “Modern/Tech.” Hat oft einen Reiniger, flacheres Oberflächenbild, geeignet für saubere Wäsche. |

| Entscheidender Vorteil | Struktur. Kaschiert Körperunreinheiten, indem es über die Haut streicht, anstatt sie zu quetschen. | Freiheit. Ermöglicht tiefe Kniebeugen und sportliche Bewegungen ohne Einschränkung. |

Kosten-Nutzen-Analyse für Bekleidungsmarken

Während die obige Tabelle den Designnutzen behandelt, Die finanziellen Auswirkungen sind für Ihre Margenstrategie gleichermaßen wichtig. Nicht nur anschauen der Denim-Preis pro Yard. Der eigentliche Kostentreiber ist der Gesamtverbrauch pro Kleidungsstück.

- 2-Wegstrecke (Die margenfreundliche Option):

- Niedrigere Effizienzkosten: 2-Der Stoff ist stabil und in der Regel in Standardbreiten erhältlich (58-60″). Dies ermöglicht enge Markierungsanordnungen und geringeren Stoffabfall.

- Strategischer Einsatz: Ideal für den Kern, SKUs mit hohem Volumen (Lagerhaltungseinheiten) bei der Aufrechterhaltung eines wettbewerbsfähigen Einzelhandelspreises ($40-$80) ist wesentlich.

- 4-Wegstrecke (Die Premium-Investition):

- Höhere Beschaffungskosten: Durch das komplexe Dual-Core-Spinnen und die Thermofixierung wird die Stofflänge im Voraus teurer.

- Das Verborgene “Ertrag” Kosten: Seien Sie sich der Konsumfalle bewusst. 4-Denim weist oft höhere Schrumpfungsraten auf (bis zu 12-15% vertikale Schrumpfung) und manchmal aufgrund der Elastizität geringere Schnittbreiten.

- Beispiel: Eine Jeans, die verlangt 1.2 Meter 2-Wege-Stoff könnten erforderlich sein 1.4 Meter 4-Wege-Stoff. Sie müssen Ihre Stückliste berechnen (Stückliste) basierend auf dieser höheren Ausbeute.

- Strategischer Einsatz: Am besten für Premium-Stufen reserviert ($100+) oder “Technischer Denim” Kollektionen, bei denen der höhere Preis durch Marketingvorteile gerechtfertigt werden kann “360° Bildhauerei” oder “Formbeständigkeit.”

So finden Sie den richtigen Partner und verwalten Ihre Kosten

Preisunterschiede: Warum 4-Wege-Stretch mehr kostet

Großhandel Denim in den USA. liegt typischerweise zwischen $4.99 Zu $9.75 pro Yard. 4-Way Stretch liegt am oberen Ende dieses Spektrums. Die Kosten werden getrieben durch:

- Patentierte Fasern: Verwendung von Markenfasern wie LYCRA® dualFX® oder T400®.

- Finishing-Prozesse: 4-Um die Abmessungen zu stabilisieren, sind spezielle Thermofixierungen und Druckschrumpfungen erforderlich.

So finden Sie zuverlässige Fabriken

Wenn Sie Lieferanten überprüfen oder Ihren Bekleidungshersteller anweisen, Stoffe zu beschaffen, Fragen Sie nicht einfach danach “Stretch-Denim.” Sie sollten dies überprüfen:

- ASTM D3107-Testergebnisse: Dadurch werden die Dehnung und das Wachstum des Stoffes gemessen (Erholung). Suchen Sie nach niedrig “Wachstum” Nummern, um sicherzustellen, dass es nicht zu Kniebeschädigungen kommt.

- Gewicht: Bestätigen Sie das Gewicht (9.5–12,5 Unzen sind Standard) passt zu deiner Saison.

- Breite: 4-Way-Stretch hat aufgrund der Schrumpfung oft eine geringere nutzbare Breite; Stellen Sie sicher, dass dies zu Ihrem Markierungslayout passt.

MOQ und Lieferzeiten für spezielle Stretchstoffe

- Großhändler: Rollenweise verkaufen (ca. 100 Yards) oder Bolzen (15 Yards). Gut zum Probieren.

- Direkt aus der Mühle: Erfordert höhere Mindestbestellmengen (oft 3,000+ Yards) ermöglicht aber auch individuelle Mischungen (Z.B., Anpassung des Polyesteranteils an die Festigkeit). Der Direktkauf bietet die größte Kontrolle über die “Tech-Rezept” Ihres Stoffes.

Letzte Gedanken

Die Wahl zwischen 2-Wege- und 4-Wege-Stretch geht über die technischen Spezifikationen hinaus. Diese Entscheidung definiert letztendlich die Identität Ihrer Marke. 2-Weg bietet das Zuverlässige, Strukturierter Komfort, den man von klassischen Jeans erwartet. 4-Art und Weise liefert die Prämie, körperbetonte Leistung, die für die Moderne erforderlich ist, aktiver Verbraucher.

Jedoch, Die Auswahl des richtigen Stoffes ist nur die halbe Miete. Um Hochleistungs-Stretch-Denim in ein perfekt sitzendes Kleidungsstück zu verwandeln, ist ein Fertigungspartner erforderlich, der sich mit wichtigen technischen Details wie Einlaufkontrolle und Schnitttechnik auskennt.

Bei Changhong, Wir sind auf die Herstellung hochwertiger Denim-Kleidung spezialisiert. Wir nutzen unsere umfassenden Branchenverbindungen, um die besten Stoffe zu beschaffen und nutzen unser technisches Fachwissen für die Abwicklung komplexer Produktionen – egal, ob es sich um Vintage-2-Wege-Stretch oder technischen 4-Wege-Stretch handelt. Wir stellen sicher, dass Ihre Designs präzise produziert werden, Minimierung von Risiken wie Beinverdrehungen oder Faltenbildung.

Bereit, Ihre Sammlung zum Leben zu erwecken? Entdecken Sie unsere OEM & ODM-Fertigung Fähigkeiten und Changhong.

Häufig gestellte Fragen

Was ist der Unterschied zwischen “Komfort-Stretch” Und “Power-Stretch”?

Diese Begriffe definieren den Grad der Dehnung, nicht nur die Richtung. Komfort-Stretch (üblich bei 2-Wege-Denim) bietet typischerweise eine Dehnung von 10–35 %, Entwickelt für Bewegungsfreiheit, ohne die Silhouette zu verändern. Power-Stretch (häufig in 4-Wege-Denim zu finden) überschreitet 40% Dehnung mit hoch “Rückzugskraft,” Entwickelt, um den Körper zu formen und Taillenlücken zu beseitigen.

Lockert sich 4-Wege-Stretch-Denim mit der Zeit??

Ja, Alle Stretch-Denims entspannen sich beim Tragen. Jedoch, 4-Way Denim mit Dual-Core-Technologie (Elastane + Polyester-Rückgewinnungsfaser) lockert sich deutlich weniger als generische Spandex-Mischungen. Der “Wachstum” sollte minimal sein, wenn der Stoff richtig thermofixiert wurde.

Ist 2-Wege-Stretch-Denim haltbarer als 4-Wege-Stretch??

Allgemein, Ja. 2-Denim hat oft eine einfachere Konstruktion mit mehr Baumwollstabilität in der Kette. 4-Wegstrecke, während langlebig, enthält mehr synthetische Filamente, die empfindlich auf hohe Hitze reagieren können (Bügeln) oder abrasive Reibung im Laufe der Jahre des Gebrauchs.

Können Sie 4-Wege-Stretch-Denim mit starkem Stonewashing reinigen??

Sie müssen vorsichtig sein. Schwer Steinwäsche oder Bleichen kann die empfindlichen Elastanfasern beschädigen, wodurch sie brechen (ergebend “sprudelnd” auf der Stoffoberfläche). 4-Way Stretch erfordert in der Regel sanftere Enzymwaschungen, um die Elastizität zu bewahren.

Welcher Stretchtyp eignet sich besser für Denim in Übergröße??

4-Way-Stretch eignet sich in der Regel besser für Anwendungen in Übergrößen. Die 360°-Beweglichkeit passt sich bequemer den Körperkurven an, ohne dass Druckstellen oder Lücken in der Taille entstehen, wohingegen 2-Wege-Stretch beim Sitzen manchmal einengend wirken kann.