Aux prises avec les coûts élevés de la production nationale de denim? NOUS. taux de travail de $15 par heure poussent les coûts de production au-dessus $40 par unité, tandis que les hubs mondiaux peuvent livrer des jeans pour moins de $10. Ce guide explore les principaux États-Unis. fabricants, évaluer la capacité de production, transparence des approvisionnements, et les effets des récents ajustements tarifaires. Nous comparons l'intégration entièrement verticale avec les modèles hybrides, aider les marques à équilibrer leurs prix, qualité, et la stabilité de la chaîne d'approvisionnement. Que vous évoluiez ou gériez vos marges, ce guide fournit des informations clés pour faire le bon choix de fabrication.

La réalité de “Fabriqué aux États-Unis” Denim

Alors que les États-Unis. les ventes au détail de denim devraient atteindre le dollar 30 milliard, la production nationale de tissus est insuffisante. La plupart des jeans étiquetés “Fabriqué aux États-Unis” commencent souvent leur voyage à l'étranger, seul l'assemblage final ayant lieu aux États-Unis.

Il existe deux principaux types de denim fabriqués aux États-Unis:

- Assemblé localement: Le tissu et les garnitures sont importés, tandis que la couture et l'assemblage ont lieu aux États-Unis. usines.

- Intégré verticalement: Rare, impliquant les États-Unis. coton, filature domestique, tissage, et couture.

Malgré une forte demande de produits nationaux, les importations sont nécessaires pour combler le déficit, comme les coûts de production aux États-Unis. sont plus élevés, notamment en raison des différences de main-d'œuvre et d'échelle. Les marques recherchant un équilibre entre qualité et coût peuvent s'associer à des fabricants comme Changhong, offrant une production mondiale efficace combinée avec les États-Unis. normes, rendre le denim de haute qualité plus accessible.

Comparaison rapide des meilleurs 10 Fabricants de jeans en denim

| Fabricant | Emplacement | Principaux produits | Force de base |

|---|---|---|---|

| Canton Changhong (Partenaire étranger) | Canton, Province du Guangdong, Chine | Jean en jean, bas tissés | Un fabricant de taille moyenne destiné à l'exportation offrant des coûts de main-d'œuvre considérablement inférieurs à ceux des États-Unis.. usines. |

| Jean Texas (Texas Jeans USA Inc.) | Asheboro, Caroline du Nord | Jeans, vêtements de travail, vêtements de lutte contre les incendies de forêt | Grande installation axée sur le « Made in USA »’ crédibilité plutôt que faible coût unitaire. |

| Todd Shelton | Rutherford-Est, New Jersey | Jeans et chinos pour hommes sur commande | Intégration verticale « directe en usine »’ modèle privilégiant l'ajustement et la personnalisation plutôt que le volume de masse. |

| Atelier de denim de Raleigh | Raleigh, Caroline du Nord | Jean lisière, denim en petits lots | Atelier en petites séries connu pour ses séries limitées, talent artistique, et une présence commerciale haut de gamme. |

| Fabrication LC King (LC King Mfg Co.) | Bristol, Tennessee | Vêtements de travail de marque Pointer, combinaisons, vestes, jeans | Usine historique (est. 1913) tirer parti du statut de patrimoine pour des prix premium. |

| Jean Dearborn | Chicago, Illinois | Jeans | Une installation de couture efficace maintient les prix inférieurs à ceux des États-Unis typiques. jeans via un personnel polyvalent. |

| Bonne entreprise de vêtements | Rivière d'automne, Massachusetts | Vêtements pour femmes, unisexe, bas en jean/coton | Idéal pour les marques émergentes avec de faibles MOQ (souvent 50 à 100 unités). |

| Moulins Vidalia (Tissu & Couper) | Vidalia, Louisiane | Tissu denim filé à l'anneau teint sur corde, paquets coupés-cousus | Une usine à grande échelle proposant des. de la ferme à l'étagère’ paquets coupés-cousus. |

| Géant américain | San Francisco, Californie (QG); Fabrication en Caroline du Nord, CS, Californie | Sweats à capuche, jeans, vêtements | Marque nationale de taille moyenne utilisant un réseau de partenaires; n'offre pas de fabrication sous contrat. |

| Détroit Denim | Détroit, Michigan | Jeans sur mesure et sur commande | Atelier artisanal spécialisé dans le jean sur mesure et sur commande. |

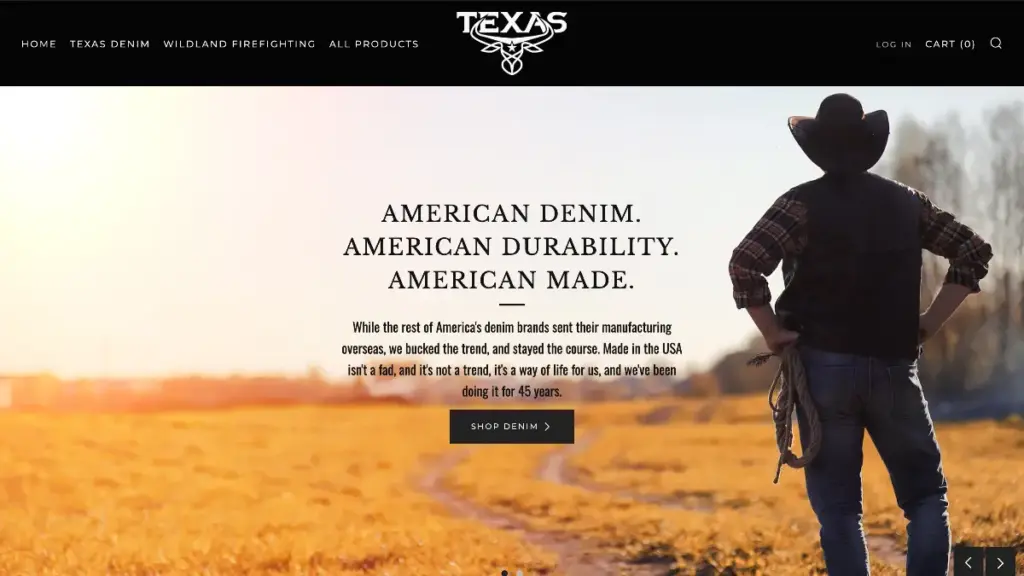

Jean Texas (Texas Jeans USA Inc.)

- Emplacement: Asheboro, Caroline du Nord

- Principaux produits: Jeans, vêtements de travail, vêtements de lutte contre les incendies de forêt

- Marchés clés: USA (Directement au consommateur, grands labels nationaux historiques)

Jean Texas, une filiale de Fox Apparel, opère à partir d'une installation de 186 000 pieds carrés à Asheboro, Caroline du Nord. Connu pour sa production en grand volume, l'entreprise fabriquait auparavant jusqu'à 60,000 paires de jeans hebdomadaires pour les grandes marques. Texas Jeans se concentre sur le denim et les vêtements de travail durables, y compris les vêtements de lutte contre les incendies de forêt, donner la priorité à la qualité et à l’authenticité plutôt qu’à la production à faible coût. Leur installation offre un niveau élevé de capacité de fabrication nationale, produisant des centaines de milliers de vêtements chaque année en mettant l'accent sur des, Produits fabriqués aux États-Unis.

Todd Shelton

- Emplacement: Rutherford-Est, New Jersey

- Principaux produits: Jeans et chinos pour hommes sur commande

- Marchés clés: Directement au consommateur

L'atelier verticalement intégré de Todd Shelton se concentre sur la personnalisation, jeans et chinos sur commande. En utilisant un modèle directement fabriqué en usine, ils assurent un contrôle précis de l'ajustement et de la qualité. Chaque vêtement est conçu pour répondre à des personnalisations de taille spécifiques, avec une production en faible volume qui met l'accent sur l'artisanat plutôt que sur la production de masse. L'atelier utilise du denim de haute qualité, offrir aux clients la possibilité de personnaliser leurs jeans. Leur approche directe au consommateur permet de proposer un produit haut de gamme à un prix compétitif., attrayant pour ceux qui recherchent une cohérence et une exclusivité.

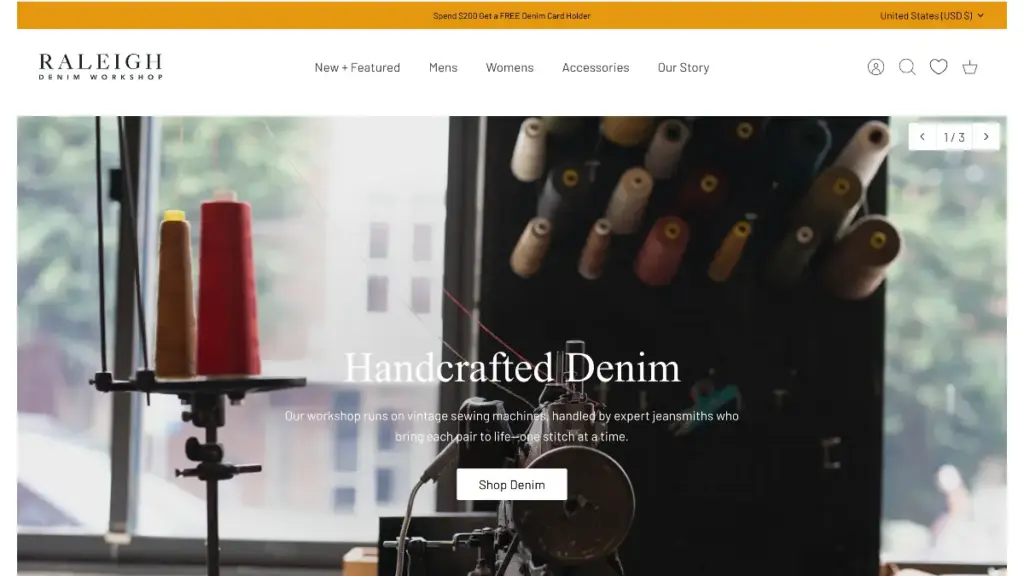

Atelier de denim de Raleigh

- Emplacement: Raleigh, Caroline du Nord

- Principaux produits: Jean lisière, denim en petits lots

- Marchés clés: Directement au consommateur, boutiques et détaillants haut de gamme

Raleigh Denim Workshop allie art et fonctionnalité dans sa production de jeans selvedge. Fonctionner avec des machines anciennes, l'usine produit du denim en petites séries, assurer une attention méticuleuse aux détails dans chaque paire. Ils mettent l'accent sur le savoir-faire et la transparence, trouver des matériaux uniques pour des séries limitées, rendre chaque produit spécial. Avec des chiffres de production de plusieurs milliers par an, Raleigh Denim reste une véritable marque artisanale, se concentrer sur la qualité plutôt que sur la vitesse. Leurs produits sont populaires auprès des boutiques et des détaillants haut de gamme., attrayant pour les clients qui apprécient le denim héritage avec une histoire.

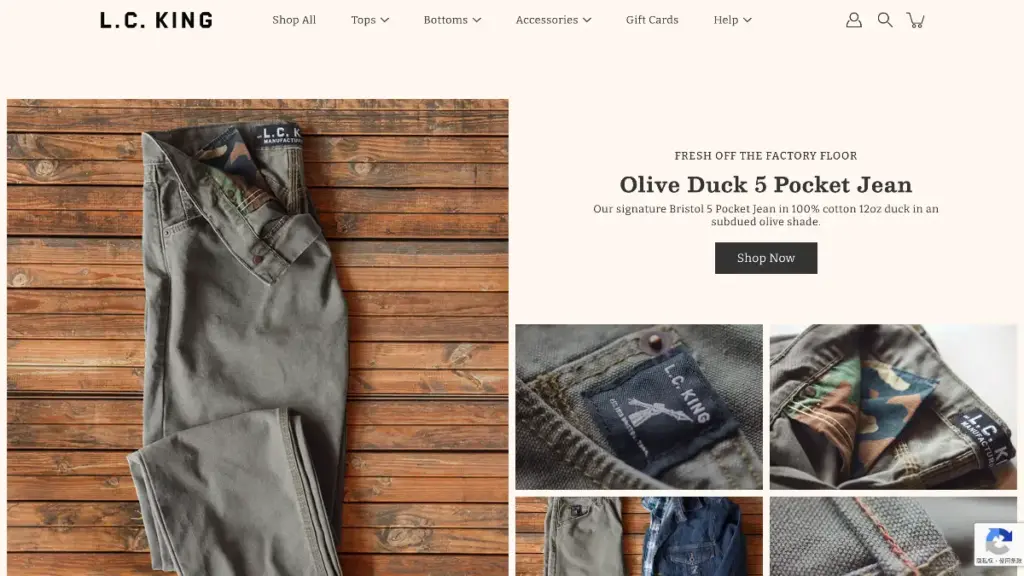

Fabrication LC King (LC King Mfg Co.)

- Emplacement: Bristol, Tennessee

- Principaux produits: Vêtements de travail de marque Pointer, combinaisons, vestes, jeans

- Marchés clés: USA (Marque du pointeur, marque privée pour les petites marques américaines)

LC King Manufacturing produit des vêtements de travail durables depuis 1913. Opérant dans une usine historique à plusieurs étages à Bristol, Tennessee, l'entreprise se spécialise dans les vêtements de travail de style héritage sous la marque Pointer Brand. Avec une capacité annuelle allant de plusieurs dizaines de milliers à plusieurs centaines de milliers, LC King est réputé pour sa robustesse, produits durables. Ils offrent des services de marque privée pour les petites marques américaines, maintenir le cap sur la qualité, authenticité, et artisanat traditionnel. Leurs vêtements de travail, y compris les combinaisons et les vestes, est conçu pour résister à des conditions difficiles, ce qui en fait un choix de confiance pour le marché intérieur.

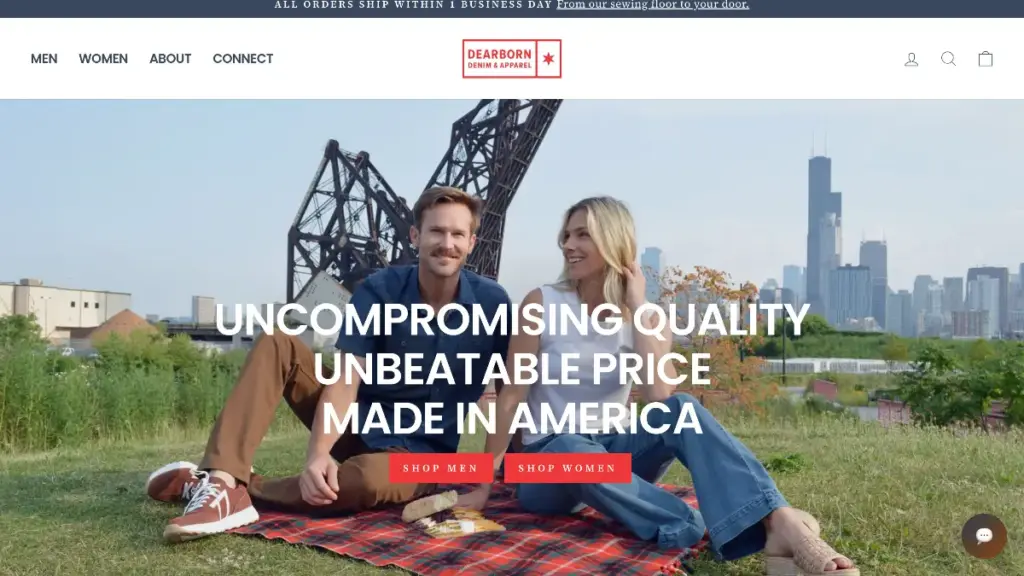

Jean Dearborn

- Emplacement: Chicago, Illinois

- Principaux produits: Jeans

- Marchés clés: Directement au consommateur, vente au détail régionale

Dearborn Denim exploite une installation dédiée à Chicago, se concentrer sur l'efficacité pour proposer des jeans fabriqués aux États-Unis à des prix compétitifs. En multiformant leur personnel, ils maintiennent des coûts de production inférieurs tout en garantissant un savoir-faire de haute qualité. L'usine produit des milliers de jeans chaque année, s'approvisionner en denim aux États-Unis. moulins, y compris en Caroline du Sud. Leurs opérations rationalisées en font un choix idéal pour les marques à la recherche de produits fiables., volume de haute qualité sans la complexité de la logistique à l’étranger.

Bonne entreprise de vêtements

- Emplacement: Rivière d'automne, Massachusetts

- Principaux produits: Vêtements pour femmes, unisexe, bas en jean/coton

- Marchés clés: Créateurs indépendants et petites marques

Good Clothing Company à Fall River fournit un soutien à la production pour les créateurs indépendants et les petites marques, les aidant à évoluer à partir de petits, des modèles sur commande à la production industrielle. Offrir de faibles quantités minimum de commande (50-100 unités), ils permettent aux marques de tester de nouvelles collections avec moins de risques. L'établissement gère diverses catégories, y compris les vêtements pour femmes et le denim, avec une production annuelle de quelques dizaines de milliers. Ils constituent un partenaire fiable pour les marques qui cherchent à se développer sans s'engager dans de gros volumes de stocks..

Moulins Vidalia (Tissu & Couper)

- Emplacement: Vidalia, Louisiane

- Principaux produits: Tissu denim filé à l'anneau teint sur corde, paquets coupés-cousus

- Marchés clés: Marques de denim premium et héritage

Vidalia Mills est l'un des principaux producteurs de tissus authentiques teints sur corde., denim filé à l'anneau en Louisiane. Avec la capacité de produire des millions de mètres par an, ils servent des marques qui exigent à la fois du volume et une qualité supérieure. En proposant des forfaits coupés-cousus intégrés, ils simplifient la chaîne d'approvisionnement, livrant un ensemble complet “NOUS. de la ferme à l'étagère” produit. Ce transparent, le processus axé sur le pays séduit les marques privilégiant les produits fabriqués aux États-Unis et s'engageant envers l'artisanat patrimonial.

Géant américain

- Emplacement: San Francisco, Californie (QG); Fabrication en Caroline du Nord, CS, Californie

- Principaux produits: Sweats à capuche, jeans, vêtements

- Marchés clés: USA (National, Directement au consommateur)

American Giant est connu pour son modèle de production nationale décentralisée, coordination du tricot, teinture, et coudre dans plusieurs États-Unis. états. L'entreprise produit des centaines de milliers d'unités par an, se concentrer sur les vêtements durables comme les sweats à capuche et les jeans. Leur approche leur permet de maintenir un contrôle strict sur la qualité en travaillant avec des partenaires spécialisés en Caroline du Nord., Caroline du Sud, et la Californie. Ce modèle leur permet de fournir des services de haute qualité, Produits fabriqués aux États-Unis à grande échelle, vendu directement aux consommateurs.

Détroit Denim

- Emplacement: Détroit, Michigan

- Principaux produits: Jeans sur mesure et sur commande

- Marchés clés: Directement au consommateur

Detroit Denim fonctionne comme un atelier à petite échelle axé sur l'artisanat, jeans sur commande. Avec un volume de production de quelques centaines à quelques milliers de paires par an, ils privilégient la qualité et le savoir-faire à la vitesse. Spécialisé dans les ajustements sur mesure, Detroit Denim s'adresse aux personnes à la recherche d'un denim personnalisé. Leur approche boutique offre aux clients un haut niveau de personnalisation, ce qui les rend idéaux pour ceux qui recherchent un style unique, jeans fabriqués à la main, plutôt que des options de marché de masse.

Canton Changhong (Partenaire étranger)

- Emplacement: Canton, Province du Guangdong, Chine

- Principaux produits: Jean en jean, bas tissés

- Marchés clés: Amérique du Nord, Europe (Clients de marque privée)

Alors que les usines américaines ci-dessus offrent de solides options de production nationale, les marques peuvent également envisager des alternatives internationales comme Guangzhou Changhong, surtout lorsque l’on cherche à s’étendre au-delà des limites nationales. Changhong gère des volumes de production mensuels allant de 50,000 à 200,000 pièces, se concentrer sur les jeans en denim et les bas tissés. Avec des taux de main-d'œuvre compétitifs nettement inférieurs à ceux des États-Unis. fabricants, Changhong permet aux marques de gérer efficacement leurs marges tout en maintenant une production élevée. Servir les marchés clés en Amérique du Nord et en Europe, leur efficacité et leur rentabilité en font un partenaire idéal pour les marques recherchant des volumes importants, une production de qualité à un prix plus compétitif.

Votre partenaire unique pour la fabrication de denim personnalisé haut de gamme

Coût par unité: USA ($40+) contre la Chine ($8+)

La différence de coût significative entre les États-Unis. et la production chinoise de denim provient principalement de la main d'œuvre et des frais généraux..

Main-d'œuvre et frais généraux

- NOUS. les usines paient du travail qualifié entre $15 et $25 par heure, avec frais généraux opérationnels 40% à 60% plus élevé qu'en Chine.

- En revanche, les coûts de main-d'œuvre en Chine varient de $1 à $5 par heure, rendre la production nettement moins chère.

Coûts de production

- Un jean 5 poches fabriqué aux États-Unis. coûte généralement entre $40 et $80 produire, tandis que la production comparable en Chine varie de $10 à $30.

- Les tarifs douaniers récents ont augmenté le coût au débarquement des importations chinoises, mais même avec un 125% tarif, les jeans importés restent moins chers que ceux fabriqués aux États-Unis.

Prix de détail

- NOUS. production à $40 par unité nécessite un prix de détail de $120 à $160, cibler les marchés premium.

- Production offshore à $15 par unité permet un prix de détail de $45 à $60, répondre aux marchés de masse.

La chaîne d'approvisionnement efficace de Changhong aide les marques à prévoir avec précision les coûts et à maintenir des prix compétitifs sans compromettre la qualité..

Approvisionnement en tissu lisière américain

Approvisionnement vrai “Fabriqué aux États-Unis” Le denim selvedge constitue un défi en raison de la taille réduite du marché et des barrières à l'entrée élevées.. Les marques doivent choisir entre des commandes personnalisées coûteuses auprès d'usines actives ou l'approvisionnement en quantités limitées de produits. “cadavres d'animaux” tissu provenant d'usines fermées.

Moulins actifs vs. Les cadavres d'animaux

Tuscarora Mills, en Caroline du Nord, est l'une des rares usines à produire encore du denim selvedge américain authentique sur des métiers à tisser Draper historiques en utilisant des produits biologiques USDA., Fibre certifiée GOTS. Cependant, leurs longs délais de livraison (8–16 semaines) et les coûts de production élevés rendent cette option coûteuse.

Alternativement, les marques peuvent acheter “cadavres d'animaux” provenant d'usines comme Cone Mills White Oak, qui s'est fermé dans 2017. Ce tissu est disponible sur les marchés secondaires, mais une fois épuisé, il ne peut pas être réapprovisionné.

Canaux d'approvisionnement

Les petites marques sont souvent confrontées à des quantités minimales de commande élevées (MOQ). Ils se tournent vers des détaillants comme EWE Fine Fiber Goods et Handa Textiles pour de petites séries de prototypes. (1–20 mètres), au prix de 26 à 28 $ par mètre, ou des grossistes comme Pacific Blue Denims pour des commandes groupées plus importantes de cadavres d'animaux, coût entre $9.75 et $13.75 par mètre.

Coût et rentabilité

Le coût des jeans fabriqués aux États-Unis est élevé. Une seule paire nécessite généralement 1.5 à 1.8 mètres de tissu, pousser le coût des matières premières au-dessus $40 par paire. En tenant compte du travail ($25–45 par unité), le coût de production dépasse $70, ce qui rend les prix de détail compris entre 165 et 260 dollars nécessaires à la rentabilité. Les marques qui visent des prix inférieurs s'associent souvent à des fabricants comme Changhong pour réduire les coûts tout en maintenant une qualité supérieure..

Conclusion

L’approvisionnement national offre une histoire patrimoniale puissante, mais les coûts élevés, dépassant souvent $40 par paire – rendent difficile la concurrence sur le marché de masse. Pour faire évoluer une marque rentable, vous avez besoin de marges plus larges et d'un approvisionnement en tissu fiable, ce que la fabrication offshore peut fournir.

En s'associant à une installation mondiale comme Changhong, vous pouvez maintenir une qualité supérieure tout en restant compétitif sur les prix. Leur production rentable, combiné avec un résultat cohérent, aide les marques à équilibrer qualité et rentabilité. Pour les marques qui cherchent à se développer sans compromettre le savoir-faire, Changhong est le partenaire qu'il vous faut. Contactez-nous aujourd'hui pour découvrir comment nous pouvons vous aider à donner vie à votre vision.

Foire aux questions

Existe-t-il des jeans encore entièrement fabriqués aux États-Unis ??

Oui, mais ils représentent une petite niche au sein du $25+ milliards de dollars américains. marché du jean. Alors que la grande majorité des jeans sont importés de pays comme le Mexique, Chine, et le Bangladesh, un groupe de marques résilient continue de couper et de coudre au niveau national, utilisant souvent des matériaux américains spécialisés.

Semblable à l’industrie de la bière artisanale, le denim national est un segment de haute qualité mais petit par rapport à la production de masse.

Pourquoi les jeans fabriqués aux États-Unis coûtent-ils généralement plus cher $200?

Les coûts de fabrication nationaux sont nettement plus élevés que les options étrangères. Produire une paire de jeans aux États-Unis coûte généralement entre $60 et $100 pour la main d'œuvre et les matériaux uniquement, contre 20 à 30 $ à l'étranger. Les détaillants triplent ce coût de production pour couvrir les frais généraux et les marges, ce qui donne un prix final de 180 $ à 300 $+.

La structure tarifaire fonctionne comme une cuisine raffinée ou une restauration rapide.; les coûts de main-d'œuvre et d'ingrédients plus élevés s'aggravent naturellement pour créer une facture finale plus élevée.

Où puis-je acheter du denim selvedge américain authentique?

Les fabricants actifs incluent Tellason à San Francisco, Imogène + Willie à Nashville, et Todd Shelton dans le New Jersey. Beaucoup de ces marques s'approvisionnent désormais en tissus auprès de Vidalia Mills en Louisiane., qui a acquis les métiers à tisser d'origine de l'usine historique de Cone Mills White Oak pour poursuivre le tissage traditionnel des lisières..

S'approvisionner auprès de Vidalia Mills, c'est comme acheter du champagne dans une région spécifique; les machines et le patrimoine définissent l'authenticité.

Les usines américaines peuvent-elles gérer des lavages vintage complexes?

Oui, des installations domestiques spécifiques offrent des finitions avancées comme les lavages enzymatiques, lavage de pierre, et traitements de résine. Cependant, la capacité est limitée, et le coût unitaire de ces lavages est souvent 2 à 5 fois plus élevé que dans les principales plateformes de denim à l'étranger en raison d'une conformité environnementale stricte et de taux de main-d'œuvre plus élevés..

Imaginez développer un film dans une chambre noire spécialisée plutôt que dans un kiosque numérique.; le processus est manuel, à forte intensité chimique, et nettement plus cher.