Equilibrar la durabilidad de la ropa de trabajo con un presupuesto estricto es una batalla constante. Quieres la sensación tradicional del algodón, pero tus clientes exigen prendas que duren más y cuesten menos.

Poly denim es la solución estratégica, Combinando comodidad natural con resistencia sintética.. ¿Pero es adecuado para tu marca?? Esta guía analiza el debate entre poliéster y algodón analizando sus distintas características., ventajas de rendimiento, y estructuras de costos para ayudarle a decidir el ganador.

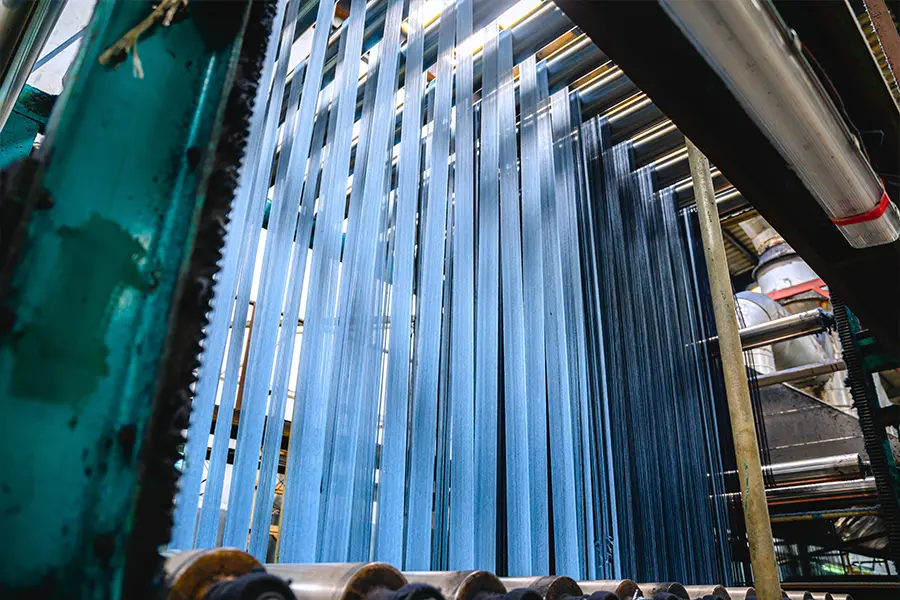

¿Qué es el denim polivinílico??

Cuando encuentras poli denim en el mercado, estás ante un tejido híbrido que mezcla fibras de algodón natural con filamentos sintéticos de poliéster.. A diferencia de los tradicionales 100% mezclilla de algodón a la que quizás estés acostumbrado, Este tejido suele incorporar un elemento estratégico. 65/35 mezcla de poliéster y algodón.

Esta composición específica es crucial para sus necesidades de fabricación.. Conserva la clásica apariencia de tejido de sarga diagonal que esperas, pero altera significativamente el comportamiento de la tela.. Tejiendo 300 a 600 Hilos de poliéster texturizados denier en la estructura., obtienes un material que es más ligero, más resistente a las arrugas, y posee una mayor resistencia a la tracción que sus homólogos totalmente de algodón.. Por eso se ha convertido en el estándar para las líneas de ropa centradas en la durabilidad..

La comparación de poliéster vs.. Mezclilla de algodón

Como gerente de adquisiciones o propietario de marca, su elección entre denim de poliéster y algodón equilibra la estética tradicional con el rendimiento industrial. Tienes que decidir si priorizas el lujo transpirable del algodón puro o la resistencia mecánica de las mezclas de polialgodón..

Para ayudarle a comparar su selección de materiales y calcular el retorno de la inversión potencial, Hemos desglosado las diferencias críticas a continuación.:

| Característica | 100% Mezclilla de algodón | Mezclilla de polialgodón. (Mezclilla polivinílica) |

|---|---|---|

| Durabilidad | Moderado; propenso a deshilacharse con el tiempo | Alto; excelente resistencia al desgarro y la abrasión |

| Rentabilidad | Más alto ($5 – $22+ por yarda) | Rentable ($4 – $15 por yarda) |

| Contracción | Alto; requiere una contracción previa rigurosa | Bajo; excelente estabilidad dimensional |

| Resistencia a las arrugas | Bajo; se arruga fácilmente | Alto; mantiene una apariencia nítida |

| Comodidad & Sentir | Alta transpirabilidad; tacto más suave | Bien; Los hilos texturizados modernos imitan el algodón. |

| Mejor aplicación | Vaqueros de primera calidad, ropa de moda | Ropa de trabajo, uniformes, líneas económicas |

Durabilidad y resistencia

La principal ventaja que se obtiene con el poli denim radica en su estructura molecular.. Los filamentos de poliéster cuentan con una tenacidad de aproximadamente 4.0 g/tex, que es significativamente más alto que el algodón. Cuando se teje en tu mezclilla, Estos filamentos actúan como una rejilla de refuerzo.. Esto significa que sus prendas resistirán mucho mejor la propagación del desgarro y la abrasión., en última instancia, extendiendo el ciclo de vida de su producto en entornos de trabajo hostiles.

Evolución del confort

Quizás le preocupe que el poliéster se sienta rígido o artificial., una crítica común en el pasado. Sin embargo, La fabricación moderna ha salvado esta brecha.. Mediante el uso de hilos de poliéster con textura de aire., Los fabricantes pueden proporcionarle polimezclilla que imita fielmente el tacto suave del algodón.. Esto le permite ofrecer la comodidad que sus clientes esperan mientras conserva el control superior de la humedad y la durabilidad que exige su resultado final..

Crea el denim perfecto para tu marca: Fabricación personalizada integrada

Teñido y estándares de calidad

Para asegurarse de obtener tela de primer nivel, Debes entender que las mezclas de algodón y polialgodón requieren protocolos de fabricación completamente diferentes.. Tratarlos igual es una receta para el fracaso de la calidad..

1. El proceso de teñido

- 100% Algodón: Utiliza un proceso monofásico estándar (típicamente teñido de cuerda o Slasher con índigo). El desafío aquí es asegurar una profunda penetración del índigo para crear el efecto deseado. “tinte de anillo” efecto para el desvanecimiento futuro.

- Mezclilla polivinílica: Requiere un sofisticado proceso de dos fases. Debemos utilizar Tintes Dispersos de Alta Temperatura para la fibra de poliéster. (a ~130°C) y Tintes Reactivos o de Cuba para el algodón.

Para propina: Si tu proveedor intenta teñirlos en un solo baño para ahorrar dinero, terminarás con el “efecto brezo” (moteado, color desigual). Exija siempre una diferencia de color Delta E inferior a 1.0 a lo largo del rollo.

2. Prioridades de control de calidad

Dado que las fibras se comportan de manera diferente., su lista de verificación de pruebas de laboratorio debe cambiar según el material:

- Para 100% Algodón (Centrarse en la estabilidad):

- Prueba de contracción (AATCC 135): El algodón es inestable.. Debe verificar que la contracción esté dentro de la tolerancia. (generalmente <3%) después del lavado, o tus prendas se deformarán.

- Sesgo o torsión: Comprueba que la pierna no se tuerce después del lavado..

- Para tela vaquera polivinílica (Centrarse en la integridad de la superficie):

- Resistencia al pilling (Norma ASTM D3512): Este es el #1 problema con los sintéticos. Las fuertes fibras de poliéster se adhieren a las bolas de pelusa.. Asegúrese de que su tela tenga una tasa de al menos un 3.5 o 4.0 calificación.

- Solidez del color al crocking (AATCC 8): Porque los tintes dispersos se depositan en la superficie del poliéster., debes realizar una prueba para asegurarte de que el color no se borre a otras superficies.

Aplicando estas normas específicas, proteges tu línea de producción de los riesgos específicos inherentes a cada tipo de tejido.

Desglose de costos de tela

Comprender la estructura de precios le ayuda a negociar mejor. Generalmente encontrará que el denim polivinílico es más rentable., normalmente van desde $4 a $15 por yarda, mientras que una calidad comparable 100% Las opciones de algodón pueden comenzar en $5 y llegar mucho más alto.

Esta ventaja de precio proviene de dos fuentes principales.:

- Costos de Materias Primas: La fibra de poliéster es generalmente más barata y de precio más estable que el algodón., que fluctúa con los rendimientos de la cosecha.

- Eficiencia de producción: La mayor resistencia del poliéster permite un tejido más rápido a alta velocidad con menos roturas del hilo., Reducir los gastos generales de fabricación que se le pasan a usted..

Sin embargo, el precio no se trata sólo de la pegatina en el rollo. Cuando se tiene en cuenta la estabilidad dimensional mejorada del poliéster denim, también ahorra dinero en desperdicio debido a contracción y segundos, reduciendo efectivamente su costo total de propiedad.

Cómo elegir entre poliéster y algodón

Decidir entre estos dos materiales requiere analizar el uso final específico de la prenda en lugar de simplemente mirar el precio.. Aquí encontrará una guía que le ayudará a alinear la elección de telas con las demandas del mercado..

Cuando elegir 100% Algodón:

Seleccione algodón puro si su mercado objetivo prioriza la transpirabilidad y la estética vintage.. Es la opción ideal para la moda premium. vaqueros donde una sensación suave al tacto y patrones de desvanecimiento naturales (bigotes y panales) son los principales puntos de venta.

Cuándo elegir Poly Denim:

Opte por el poliéster cuando la durabilidad y el control de costos son primordiales. Esta es la elección estratégica para:

- Ropa de trabajo industrial: Donde la resistencia al desgarro es fundamental para la seguridad.

- Uniformes Corporativos: Donde el color constante y la resistencia a las arrugas reducen el mantenimiento de los empleados.

- Líneas conscientes del presupuesto: Cuando es necesario lograr un precio minorista competitivo para proteger los márgenes.

Consejos de cuidado y mantenimiento

Para marcas de ropa, Proporcionar instrucciones de cuidado claras es una parte vital del servicio al cliente.. Un mantenimiento adecuado prolonga la vida útil de las prendas de polimezclilla y reduce las devoluciones por daños..

Estas son las mejores prácticas para incluir en las etiquetas de cuidado o guías de productos.:

- Control de temperatura: Aconsejamos lavar en agua tibia. (no excediendo los 60°C/140°F) para prevenir el daño de la fibra.

- Preservar el color: Se recomienda darle la vuelta a las prendas antes de lavarlas para reducir la abrasión en la cara teñida..

- Evite el cloro: Advierte explícitamente contra el cloro, ya que puede degradar el componente de algodón de la mezcla.

- planchado: Si es necesario planchar, debe hacerse en una configuración más baja que la del algodón estándar para evitar “acristalamiento” las fibras sintéticas.

Pensamientos finales

Al final, La elección entre mezclilla de poliéster y algodón depende de su equilibrio de costos específico., durabilidad, y atractivo estético. Mientras que el algodón puro sigue siendo el estándar de la moda de estilo vintage, Las mezclas de polietileno ofrecen la resistencia resistente y la estabilidad de precios esenciales para la ropa de trabajo industrial..

Para ejecutar esta visión, necesita un socio de fabricación capaz de manejar diversas especificaciones de materiales. Changhong es un fabricante líder de prendas de mezclilla, proporcionando de extremo a extremo Servicios OEM y ODM. Desde el abastecimiento de la tela hasta la costura final, Ayudamos a las marcas a producir jeans y ropa de trabajo de alta calidad que satisfagan las demandas precisas del mercado..

Preguntas frecuentes

¿El poli denim se desvanece como 100% algodón?

Generalmente, No. Las fibras de poliéster no destiñen mucho y retienen el tinte mucho mejor que el algodón.. Esta es una ventaja significativa para los uniformes corporativos que deben lucir “nuevo” por más tiempo, pero hace que el denim polivinílico sea menos adecuado para líneas de moda que requieren un auténtico desvanecimiento vintage o “bigote” efectos.

La mezclilla de polialgodón se forma pastilla después del lavado.?

La formación de bolitas puede ser un problema con las mezclas de menor calidad, pero es prevenible. El denim de poliéster de alta calidad utiliza hilos de algodón de fibra larga y poliéster con textura de aire para minimizar la migración de fibras.. Al abastecerse, Pregúntele a su fabricante si usan “chamuscando” Procesos para quemar las fibras que sobresalen., lo que reduce significativamente el riesgo de formación de bolitas.

¿Agregar poliéster hace que la mezclilla sea elástica??

Este es un error común. El poliéster añade resistencia y durabilidad., no estirar. Si necesitas elasticidad para mayor comodidad. (jeans ajustados o ropa de trabajo activa), debes buscar una mezcla que incluya elastano o spandex, no solo poliéster.

¿El denim de poliéster es lo suficientemente transpirable para climas cálidos??

Mientras 100% el algodón es naturalmente más transpirable, El poli denim moderno a menudo está diseñado con propiedades que absorben la humedad.. Para ropa de trabajo resistente en ambientes calurosos, una mezcla de poliéster más liviana (alrededor 9-10 onz) En realidad, puede funcionar mejor que el algodón pesado al transportar el sudor fuera del cuerpo en lugar de absorberlo..

¿Existen opciones ecológicas para el poli denim??

Sí. La industria avanza cada vez más hacia el Poliéster Reciclado (PET), que está hecho de botellas de plástico posconsumo. El uso de rPET mezclado con algodón orgánico o BCI permite a las marcas mantener los beneficios de durabilidad de las fibras sintéticas al mismo tiempo que cumplen con los objetivos de sostenibilidad y reducen los desechos plásticos..