Si necesita lanzar colores de temporada sin MOQ elevados (Cantidades mínimas de pedido) de tela teñida con hilo, bull denim es tu mejor opción.

El denim índigo tradicional te limita a los tonos azules. mezclilla de toro, sin embargo, sirve como flexible, base sin teñir. Permite almacenar crudo “Griego” productos y teñirlos sólo cuando los datos de ventas confirmen qué colores son realmente tendencia. Esta estrategia te ayuda a asegurar el peso pesado., Ropa de trabajo auténtica que tus clientes exigen., mientras reduce drásticamente el riesgo de su inventario.

Aquí está su guía técnica para el abastecimiento., tratamiento, y capitalizando el bull denim.

Por qué Bull Denim es ideal para teñir prendas

Para tomar decisiones de abastecimiento informadas, primero necesitas una definición técnica clara.

¿Qué es Bull Denim??

El denim Bull es un peso pesado (normalmente de 10 a 14 onzas), 100% tela de algodón tejida con un 3/1 construcción de sarga.

Distinto del denim estándar, que se produce con hilos índigo preteñidos, El denim de toro está tejido de materiales naturales., hilos sin teñir (productos grises). Este específico “blanco” El estado está diseñado intencionalmente para teñir piezas o teñir prendas después de la producción., haciéndolo estructuralmente diferente de los jeans de moda destinados a decolorarse.

Para entender por qué esto lo convierte en la opción preferida para el teñido de prendas., hay que mirar su ingeniería física. Mientras que la mezclilla estándar está diseñada para perder color, bull denim está diseñado para sujetarlo.

El “Sin teñir” Ventaja: Saturación de color real

La razón principal por la que eliges el toro tela de mezclilla es el estado del hilo.

- El problema con la mezclilla estándar: Sus hilos de urdimbre están pre-teñidos con índigo.. El núcleo permanece blanco., y el tinte se asienta en la superficie. No puedes teñirlo fácilmente para limpiarlo., color sólido.

- La solución Bull Denim: Porque está tejido con materiales naturales., Hilos sin teñir tanto en urdimbre como en trama., la tela actúa como base neutra. Esto le permite lograr profundidad, Saturación de color uniforme que penetra en toda la fibra.. Si quieres un negro azabache o un amarillo canario vibrante, la tela absorbe el tinte de manera uniforme sin la interferencia de una base azul.

3×1 Construcción de sarga: Construido para resistir la tintorería

El teñido de prendas es un duro proceso industrial que implica altas temperaturas y fuertes movimientos mecánicos.. Necesitas una estructura de tela que no se deforme.

- Integridad estructural: Bull denim utiliza un denso 3/1 tejido de sarga (la trama pasa por tres extremos de la urdimbre). Esto crea una, estructura más pesada en comparación con el estándar 2/1 Telas encontradas en sargas más ligeras..

- El resultado: Mantiene su forma y tacto robusto incluso después de hervir baños de tinte y lavado de piedra industrial, asegurando que su prenda final luzca premium, no endeble.

Las ventajas comerciales de Bull Denim para su negocio

Calidad del PFD y vitalidad del color

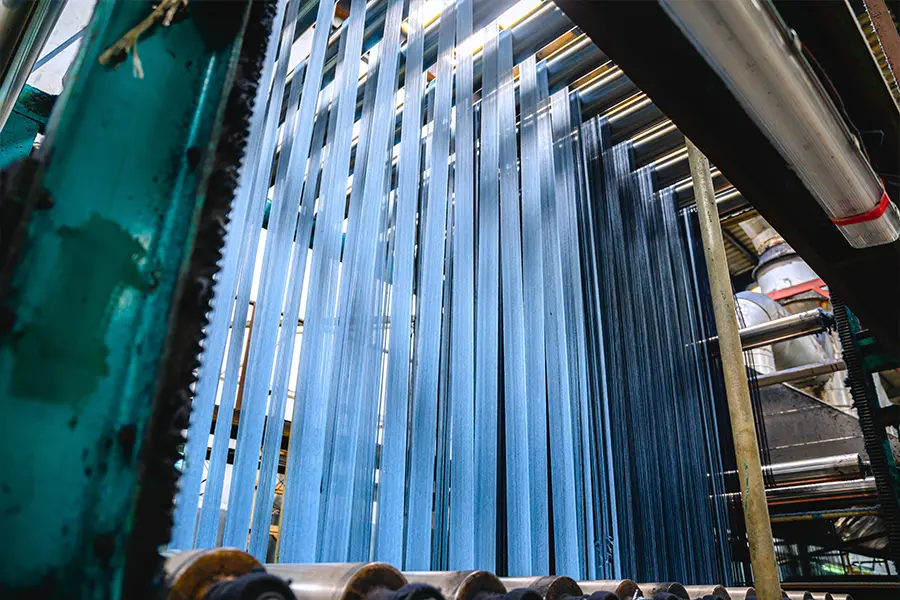

La mayor parte del denim se vende como PFD (preparado para teñir). Esta designación significa que la tela ha sido sometida a un lavado y blanqueo industrial para eliminar ceras e impurezas naturales.. Esto es importante porque el proceso hace que el algodón sea muy absorbente., asegurándose de que cuando utilice tintes reactivos con fibra en un baño alcalino (60–80°C), El color se une permanentemente a la fibra., creando tonos vibrantes que no sangrarán.

Reducción de los plazos de entrega con programas de teñido de prendas

El uso de PFD bull denim separa la compra de telas de las decisiones de color. Puedes asegurar tu stock de telas con meses de antelación, pero espera para decidir los colores finales hasta semanas antes del lanzamiento.. Esta agilidad le permite reaccionar más rápido que los competidores que todavía esperan rollos teñidos con hilo personalizado..

Reducir los riesgos de inventario mediante el teñido impulsado por la demanda

En lugar de comprometer su presupuesto a 5,000 yardas de un color específico que podrían no venderse, Mantienes la tela blanca.. Si un color específico comienza a ser tendencia, tiñes los espacios en blanco inmediatamente. Este “tinte bajo demanda” El modelo es la forma más eficaz de proteger sus márgenes de beneficio..

Desbloquee la fabricación de mezclilla personalizada premium

Cómo lograr acabados suaves y vintage

El denim crudo llega del telar, rígido y cargado de almidón. Transformar este material industrial en una prenda lista para la venta requiere una secuencia específica de acabados..

Del rígido Greige a la lujosa suavidad

La rigidez inicial proviene del apresto de almidón utilizado para proteger los hilos durante el tejido.. Para eliminar esto, El proceso de acabado industrial generalmente comienza con el desencolado enzimático. (usando alfa-amilasa en 60 °C). Una vez que el almidón se descompone, La aplicación de suavizantes de ácidos grasos relaja las fibras gruesas., dándole a la tela pesada una caída notablemente más suave.

Lavado Industrial para el “Vivido en” Mirar

El lavado industrial le permite evitar por completo el período de rodaje, entregando el suave, textura desgastada que los consumidores esperan recién salida del estante.

- Lavado de enzimas: Las enzimas celulasas erosionan suavemente las fibras de la superficie para crear una superficie lisa..

- Lavado de Piedras: Dar vueltas con piedra pómez suaviza físicamente la tensión. 3/1 tejer, dándole a tu prenda un aire relajado, sensación cómoda en la mano inmediatamente.

Equilibrando la apariencia vintage con la durabilidad

Si quieres un mezclilla desgastada mirar, La tecnología láser es el estándar moderno.. Crea patrones antiguos en la tela en segundos.. Sin embargo, Tenga en cuenta que el desvanecimiento por láser es eficiente pero agresivo: puede reducir la resistencia a la tracción entre un 7% y un 8%.. Su equipo de producción debe equilibrar la intensidad del desvanecimiento para garantizar que la tela permanezca lo suficientemente fuerte. (arriba 600 norte) para uso diario.

Cómo controlar los riesgos de producción

El abastecimiento de tejido PFD plantea desafíos específicos en torno a la contracción y la estabilidad del grano. Así es como puede prevenir defectos comunes.

Gestión de tasas de contracción en corte y costura

La mezclilla de toro se encoge. Si usas tela cruda, Espere que el largo se reduzca entre un 12% y un 14% después del primer lavado.. Para mitigar esto, siempre debes pedir Sanforizado (inencogible) rollos. Este proceso mecánico compacta la tela., reducir la contracción residual a un manejable 3-5%, lo cual es esencial para una clasificación de patrones precisa.

Prevención de torsión y desviación

La tensión diagonal en un 3/1 la sarga puede hacer que las perneras de los pantalones se tuerzan (esfuerzo de torsión) después del lavado. Para evitar esto, asegúrese de que su fábrica realice un “sesgado” Corrección durante el proceso de acabado.. Además, Verifique que sus marcadores estén cortados estrictamente a lo largo de la línea de la fibra para minimizar la torsión en la prenda final..

Tintes reactivos vs.. Tintes pigmentarios

La elección del tinte impacta en la estética final.. Elige tintes reactivos si quieres sólidos., colores uniformes que parecen nuevos durante años. En cambio, Elige tintes pigmentados si quieres que el color se desvanezca en las costuras y los bolsillos., creando una cosecha “lavado” estético.

Cómo conseguir mezclilla Bull de calidad

Identificación de defectos y grados de calidad

Para ropa de trabajo o tapicería, Los controles visuales no son suficientes.. Debe solicitar los resultados de la prueba de abrasión de Martindale. (apuntar a >40,000 frota) y datos de resistencia a la tracción. También, Inspeccione cuidadosamente los rodillos PFD para ver si “volar” (contaminación coloreada)—Estos son invisibles en la tela blanca, pero aparecen como motas oscuras permanentes una vez que tiñes la tela..

Comparación de costos de Bull Denim vs.. Telas teñidas de hilo

- El costo: La mezclilla Bull generalmente cuesta entre un 20% y un 30% más por yarda que la mezclilla liviana estándar porque usa más algodón. (peso más pesado) y tarda más en tejer.

- El valor: Usted compensa este costo de material eliminando el dinero de descuento perdido en el inventario de colores no vendido..

Preguntas críticas para los proveedores de telas

Antes de firmar la Orden de Compra, haz estas tres preguntas:

- “¿Este grado de PFD está diseñado específicamente para teñido reactivo??” (Asegura la absorbencia).

- “¿Cuál es la contracción residual garantizada??” (Previene errores de tamaño).

- “¿Tiene en stock productos crudos consistentes para pedidos repetidos??” (Garantiza la continuidad del suministro).

¿Es Bull Denim adecuado para su colección??

El denim Bull ofrece una clara compensación: usted paga una prima por el peso y la durabilidad del material, pero obtienes la capacidad de reaccionar instantáneamente a las tendencias del mercado..

Sin embargo, La tela de alta calidad requiere precisión. fabricación convertirse en una prenda premium. Debido a los desafíos únicos de contracción y distorsión discutidos anteriormente, necesita un socio fabricante que sepa cómo cortar y coser correctamente la mezclilla antes de que entre al baño de tinte..

Aquí es donde Changhong sobresale. Como fabricante líder de prendas de mezclilla, Changhong ofrece servicios integrales Soluciones OEM y ODM. Ya sea que necesite ayuda para conseguir el denim bull PFD perfecto o necesite una fábrica que pueda gestionar con precisión el complejo proceso de corte y costura para colecciones teñidas en prendas., Changhong garantiza que su producto final cumpla con los estándares de calidad internacionales.

Listo para asegurar la mejor fabricación para su próxima colección? Contáctenos hoy para explorar nuestras capacidades y discutir sus requisitos personalizados.

Preguntas frecuentes

¿Cuál es la diferencia entre bull denim y duck canvas??

Esta es la confusión de abastecimiento más común.. Si bien ambos son tejidos pesados de algodón., la diferencia está en el tejido. Bull denim es un tejido de sarga (lineas diagonales), lo que le da una mejor caída y suavidad para la ropa.. El lienzo de pato es un tejido liso. (rayado), lo que lo hace más rígido, halagar, y más resistente al agua, pero menos cómodo para pantalones o chaquetas.

¿En qué se diferencia el bull denim de la sarga de algodón normal??

Todo el denim de toro es de sarga., pero no toda la sarga es mezclilla. “Estándar” tela asargada (como chinos) suele ser más claro (7–9 onzas) con un mas fino 2/1 tejer para una apariencia más elegante. La mezclilla Bull es significativamente más pesada (10 oz+) con un mas grueso 3/1 construcción. Eliges bull denim cuando quieres la textura resistente y el peso visual de los jeans., en lugar del acabado plano de los pantalones.

¿Está disponible el denim bull con elasticidad? (elastano)?

Sí. Mientras que el bull denim tradicional es 100% algodón rígido, Proveedores modernos como Changhong pueden obtener mezclilla elástica (típicamente 98% algodón / 2% elastano o spandex). Esto le permite lograr el aspecto auténtico de sarga pesada con el ajuste cómodo necesario para los mercados de la moda contemporánea..

¿Se puede utilizar bull denim para tapicería del hogar??

Absolutamente. Debido a su alta resistencia a la tracción y a la abrasión (a menudo excediendo 40,000 frotaciones martindale), bull denim es la mejor opción para fundas y tapicería resistente. Su capacidad para teñirse en piezas significa que puede combinarlo fácilmente con paletas de colores de diseño de interiores específicas..

¿Puedo combinar colores Pantone específicos en bull denim??

Sí. Esta es una ventaja comercial principal.. Dado que PFD bull denim comienza como una base blanca neutra, Las casas de tinte pueden coincidir exactamente con Pantone. (TCX) estándares, brindándole control creativo total sobre su paleta de colores de temporada, a diferencia de las telas preteñidas, que se limitan a los colores de fábrica.