Seeing a price gap between $2.00 and $20.00 per yard is confusing. Is the expensive option really ten times better? Often, the answer is no. You might simply be paying for the middleman’s overhead.

This guide peels back the layers on real 2026 manufacturing costs and hidden fees. Let’s look at the numbers so you can stop overpaying and start sourcing with confidence.

What Should You Actually Pay? 2026 Global Benchmarks

(Note: All prices below refer to estimated FOB (Free on Board) pricing for standard wholesale quantities.)

Instead of guessing, use this benchmark table to evaluate supplier quotes. Prices vary based on origin, labor costs, and cotton availability.

| Origin | Est. Wholesale Price (Per Yard) |

Best For… |

|---|---|---|

| China |

$1.65 – $2.75 (Commodity) $3.50 – $6.50 (Premium/Tech) |

Volume & Innovation. The global leader for scalability. Top-tier mills now produce high-end recycled and tech denim (e.g., Coolmax) that rivals European quality at 20–30% lower costs. |

| India | $3.20 – $5.80 | Organic Cotton. Excellent value for GOTS-certified organic options due to abundant local cotton supply. |

| Turkey | $6.50 – $8.50 | Premium Sustainability. Known for proprietary blends, high-end finishing, and proximity to European markets. |

| USA / Japan | $15.00 – $30.00+ | Luxury Niche. Selvedge, artisanal, and heritage denim for high-price-point boutique brands. |

Why Does One Fabric Cost $2 and Another $12?

Don’t let the brand name fool you. The real price drivers are the physics and chemistry of production. Here is what you are actually paying for.

Raw Material Volatility (Cotton vs. Synthetics)

Raw materials account for 60–70% of the total denim fabric cost. The price you pay is often indexed to global cotton futures. While 100% cotton is the standard, poly-blends (synthetics) offer a lower-cost alternative that can help you hit aggressive price points without sacrificing durability.

The “Weight” Penalty

Price correlates directly with weight (oz/yd²). A heavyweight 14 oz denim requires significantly more cotton yarn per yard than a lightweight 10 oz fabric. If you are budget-constrained, consider dropping from 13 oz to 11.5 oz—the visual difference is minimal, but the cost savings are substantial.

The “Green” Premium & Sourcing Strategy

Sustainability comes with a cost, but where you buy matters more than what you buy.

- Retail Scenario: Boutique retailers often sell GOTS-certified organic denim for $18.00–$22.00/yard.

- Wholesale Reality: By sourcing directly from efficient manufacturers (like Changhong), you can secure the same GOTS-certified bulk quality for $4.50–$8.50/yard.

Buying by the Yard vs. the Pound: How Not to Get Overcharged

The Golden Rule: Woven denim is sold by length (Yards/Meters). Knits and scraps are sold by weight (Pounds/Kilos).

The Retail Trap vs. Wholesale Reality

If you are calculating costs based on prices you see online, you are likely overestimating your budget.

- Designer/Retail Price: $15.00 – $21.00 per yard (includes huge markups for cutting small quantities).

- Factory Direct Price: $1.65 – $2.75 per yard (base industrial rate).

When Should You Buy by the Pound?

You should only be paying “per pound” if you are buying:

- Knitted Denim: Which behaves like t-shirt fabric.

- Stock Lots / Deadstock: Leftover rolls sold by weight to clear warehouse space.

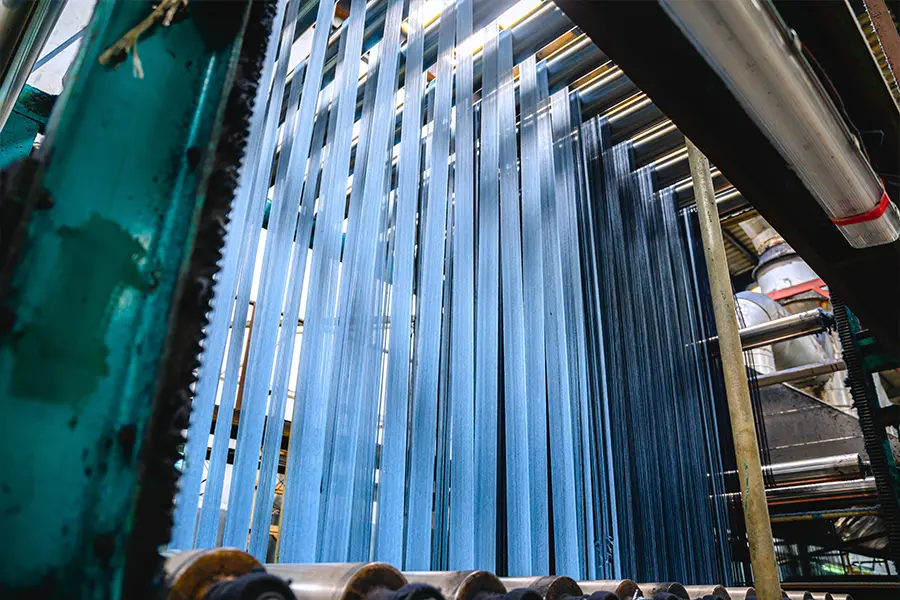

- Greige Goods: Unfinished, undyed fabric straight from the loom.

From Fabric to Final Stitch: Your One-Stop Denim Partner

The Hidden Costs: 3 Things That Eat Your Margins

Experienced buyers know that the lowest price per yard doesn’t always equal the lowest cost per garment. To avoid margin erosion, ensure you align with your manufacturer on these three technical specifications before finalizing a PO.

1. “Cuttable” Width vs. Full Width

A common pitfall is calculating yield based on the full roll width (e.g., 60″).

- The Reality: Due to selvedge pinholes and edge weaving tension, the actual Cuttable Width might only be 58″.

- The Cost Impact: A 2-inch loss in width can break your marker efficiency, forcing you to use 5–10% more fabric per garment.

- Action: Always confirm the Guaranteed Cuttable Width with us before estimating your consumption.

2. The Shrinkage Factor

Denim is alive. Unlike stable synthetics, cotton denim shrinks, significantly impacting your “Buy Yield.”

- Rigid Denim: High shrinkage (10–15%) means you must purchase significantly more yardage to achieve the final garment measurements.

- Stretch/Sanforized: Lower shrinkage (2–5%), offering better yield predictability.

- Action: We provide detailed shrinkage reports (warp/weft) with every sample roll to help you calculate exact purchasing needs.

3. Marker Efficiency Reality Check

Are you cutting a full size run or single sizes?

- Optimization: A full size run (S–XL nested together) typically achieves 85%+ efficiency.

- The Gap: If you estimate costs based on 100% efficiency, you will fall short. Always buffer 3–5% for physical loss (knots/end-of-roll) to protect your production run.

Where Your Budget Goes: Stockists vs. Factory Direct

The single biggest factor influencing your unit price isn’t the cotton futures—it’s who you cut the check to. It’s important to know if you are paying for the product or paying for someone else’s storage.

1. The Stockist (Buying Convenience)

Stockists (or Jobbers) are domestic suppliers who hold inventory so you don’t have to.

- The Price Tag: $6.00 – $12.00+ per yard.

- The Trade-off: You are paying a 200%–400% markup for speed. It’s like buying milk at a 24-hour convenience store instead of a supermarket. Great for sampling, but it hurts your bottom line in production.

- Best For: Samples, rush orders, and small capsule collections.

2. Factory Direct (Buying Value)

Sourcing directly from a manufacturer like Changhong cuts out the middleman fees entirely.

- The Price Tag: $1.65 – $4.50 per yard.

- The Trade-off: You get the lowest possible price, but you need to plan ahead (production lead time) and commit to a volume order (MOQ).

- Best For: Main production runs where profit margin matters most.

Let’s Look at the Numbers: If you make 1,000 pairs of denim jeans using a Stockist ($8/yd), you spend $12,000 on fabric. If you go Factory Direct ($2.50/yd), you spend only $3,750. That’s $8,250 in extra profit just by changing who you buy from.

Smart Sourcing Starts Here

Managing denim costs requires more than just hunting for the cheapest fabric. The real secret is shortening your supply chain.

- Buying from a middleman? You pay for their storage and profit.

- Buying direct? You pay for the product.

Partnering directly with a full-service manufacturer like Changhong eliminates the markups. With over 20 years of industry expertise and a vertically integrated supply chain, we offer comprehensive OEM/ODM solutions tailored to your specific market needs. Whether you need rapid custom development or sustainable organic options, we provide the factory-direct pricing ($2-$5/yard) and consistency you need to scale.

Ready to optimize your production costs? Contact us today for a quote on your next denim collection.

Frequently Asked Questions

How much does denim fabric cost?

In 2026, denim fabric generally costs between $5 and $20 per yard for retail or small-quantity purchases.

Basic quality starts around $5 per yard, mid-range is $8–$15, and premium or specialized denim can exceed $20.

For bulk manufacturing, prices are lower, typically $5–$8 per yard from China and $7–$12 per yard from U.S. sources.

Is denim fabric considered expensive?

Denim is generally considered a mid-priced fabric. It’s more durable and complex to produce than basic cotton but more accessible than luxury textiles.

While standard retail prices are $5–$20 per yard, direct mill sourcing for bulk orders can be as low as $2.50–$5.00 per yard.

Specialty and designer denims can reach $50–$60 per yard, but this represents a small, high-end niche.

How much denim fabric is needed for one pair of pants?

A standard pair of adult jeans requires about 1.5 to 2.0 yards of fabric. This assumes the fabric has a standard width of 55–60 inches.

If you are using narrower selvedge denim, which is often around 30 inches wide, the requirement increases to about 2.5 yards.

How is denim fabric priced by the pound?

At the wholesale or mill level, commodity denim fabric costs approximately $2–$4 per pound.

This is a conversion from the more common per-yard pricing, with most 10–14 oz denim averaging around $3 per pound in bulk orders.

What is the typical cost for 12 oz denim per yard?

For retail purchases, a standard 12 oz denim fabric typically costs between $15 and $21 per yard. This weight is common for sturdy, classic jeans.

When sourced in bulk directly from mills like Changhong, the same fabric can cost significantly less, often in the range of $1.40 to $2.75 per yard.