Chambray and denim may share a similar indigo aesthetic, but their physical properties are distinct. In production, they require different handling and yield completely different results. Choosing the wrong fabric affects more than just the look; it compromises the drape, the breathability, and the overall quality of the garment.

At Changhong, we know that precise material specification is critical for a successful collection. As your manufacturing partner, we help you navigate these technical nuances, ensuring the fabric you choose accurately supports your design intent.

What‘s the Core Difference between Chambray and Denim?

While both fabrics typically start with cotton and indigo dye, their structural basis is fundamentally different. It comes down to the textile architecture.

What Makes Chambray Unique?

Chambray is defined by a 1/1 plain-weave construction, the simplest and most structurally balanced of all weaves.

- The Mechanics: The warp and weft threads cross at right angles, aligning in a strict “one-over, one-under” pattern. This creates the maximum number of interlacing points.

- The Result: This high frequency of intersections holds the yarns firmly in place, giving chambray excellent structural stability (less skewing). Visually, because the colored warp and white weft are equally visible, it creates that signature “mottled” or “salt-and-pepper” depth that looks consistent from every angle.

What Defines the Denim Look?

Denim is a robust fabric characterized by a twill weave (typically 3/1 or 2/1).

- The Mechanics: The weft thread floats over two or more warp threads before diving under. These “floats” allow the yarns to be packed closer together than in a plain weave, resulting in a significantly higher thread count and density per square inch.

- The Result: This structure creates the iconic diagonal rib (wale). Most standard denim uses a Right-Hand Twill (RHT), which adds to its crisp, rugged character. The dominance of the warp yarn on the face is what gives denim its deep, solid blue intensity compared to chambray’s lighter, heathered look.

How to Spot the Difference Instantly

When you are inspecting fabric headers or swatches, don’t just trust the label. Look for these two tell-tale signs:

- The “Underside” Test: Chambray looks virtually the same on both sides (a 1:1 ratio). Denim’s underside is predominantly white because the twill weave hides the blue warp yarns on the back.

- The “Luster” Check: Because denim has longer “floats” (yarns sitting on top), it reflects light differently. New denim often has a slight sheen or luster, whereas chambray, with its frequent interruptions of interlocking yarns, typically has a flatter, more matte finish.

Quick Comparison: Chambray vs. Denim

| Category | Chambray | Denim |

|---|---|---|

| Construction & Look |

Plain Weave (1/1): Mottled “salt-and-pepper” look. Reversible: Looks the same on front and back. |

Twill Weave: Signature diagonal rib texture. One-Sided: Back is mostly white (weft). |

| Weight & Feel |

Lightweight (3.5–5.5 oz): Flowy and breathable. Soft Structure: Drapes closely to the body. |

Heavyweight (6–21 oz): Dense and rigid. Stiff Structure: Holds shape (collars/cuffs). |

| Aging & Performance |

Even Fading: Maintains consistent color. Moderate Strength: Best for loose fits. |

High Contrast Fading: Develops whiskers/patina. High Durability: Built for friction/wear. |

Elevate Your Brand with Custom Denim Solutions

Differences in Weight & Feel: Choosing Comfort for Your Design

The weight you specify dictates the personality of your garment. It’s the deciding factor between a shirt that flows effortlessly and one that feels stiff and boxy against the body.

Lightweight vs. Heavyweight Options

- Chambray (The Standard for Shirting): Typically 3.5 to 5.5 oz/yd². This is your go-to for breezy summer shirts that need to feel weightless.

- Denim (The Durable Option): Usually 8 to 21 oz/yd². Even “Lightweight Denim” (4–6 oz) will feel denser than a 5 oz chambray because the twill weave packs more cotton into every square inch.

Softness and Draping

- Chambray: Offers a fluid drape. It moves easily with the wearer, making it suitable for relaxed, unconstructed fits.

- Denim: Even in lighter weights, denim has “structure.” It is excellent for holding rigid shapes, like a crisp collar or a defined cuff. But it does not drape as loosely as plain weave.

Breathability and Wearability

- Chambray: The plain weave naturally creates minute gaps between yarns, providing excellent air permeability.

- Denim: The dense twill construction blocks wind better, but traps heat. For high-humidity markets, chambray is significantly more breathable.

Aesthetic Differences: Color & Character

Your design isn’t static. You need to anticipate not just how the garment looks on the rack, but how it will evolve after a year of wear.

The Charm of Fading Denim (Ring Dyeing)

Denim is prized for its ability to evolve.

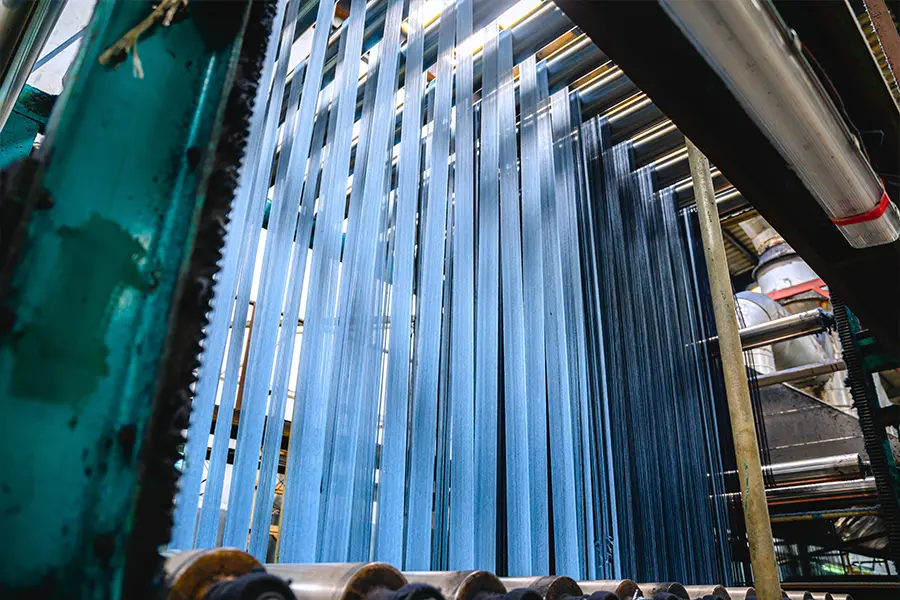

- The Process: Industrial denim fabric uses continuous warp-yarn dyeing (rope dyeing) with indigo vat dyes. The dye only penetrates the surface of the yarn (Ring Dyeing), leaving the core white.

- The Look: As the garment is worn and washed, the surface dye chips away, revealing the white core. This creates the coveted “fades,” whiskers, and high-contrast aging that chambray cannot replicate.

Texture Profile: Regular vs. Slubby

- Denim: Often utilizes “Slub Yarns” (yarns with intentional thickness variations). This creates a vertical or cross-hatch texture that gives the fabric a rugged, vintage character.

- Chambray: Typically uses regular, even yarns. The goal is a clean, uniform surface. It offers a more polished aesthetic that does not look distressed or worn-in.

The Consistent Beauty of Chambray

Chambray maintains a consistent shade over time. Because the dye usually penetrates the yarn more fully (or uses reactive dyes), it may soften in color, but it will not develop the high-contrast patina associated with jeans.

Durability & Care: What Your Customers Will Experience

Durability is non-negotiable. You need to select a fabric that withstands the mechanical stress of daily wear and repeated washing cycles.

Wear Resistance: Built to Last?

- Denim: High durability. The twill structure is engineered for high tear strength, making it ideal for pants, jackets, and workwear that must withstand heavy use.

- Chambray: Comfortable, but lighter. Being a plain weave, it is more susceptible to surface abrasion. It is perfect for shirts, but less suitable for high-stress garments like trousers.

Managing Shrinkage for a Better Fit

- Denim Risk: Unsanforized (raw) denim can shrink up to 10% due to yarn tension.

- The Fix: At Changhong, we manage this through industrial pre-shrinking and stabilizing washes, ensuring the garment size remains accurate after purchase.

Best Applications of Chambray vs. Denim

Matching the fabric to the silhouette is where design meets engineering. A fabric that works perfectly for a loose tunic will fail disastrously as a fitted pair of trousers.

Here is a detailed breakdown of how to apply these fabrics based on our manufacturing experience.

Fabric Selection Guide by Garment Type

| Garment Category | Ideal Fabric | Target Weight | Factory Insight for Production |

|---|---|---|---|

| Western / Workwear Shirts | Denim | 6–8 oz | Use heavy top-stitching thread to emphasize the seam puckering and washing effects. |

| Resort / Casual Shirts | Chambray | 3.5–5 oz | Use finer thread and French seams. Avoid heavy collars as the fabric lacks support. |

| Standard 5-Pocket Jeans | Denim | 11–14 oz | The only choice. Chambray lacks the tensile strength to hold rivets and tight fits. |

| Wide-Leg Summer Pants | Chambray | 5–6 oz | Must be a loose fit. Tight chambray pants will suffer from “seam slippage” (yarns pulling apart). |

| Tiered / Gathered Dresses | Chambray | 4–5 oz | Excellent for gathering. It creates volume without adding bulk or weight. |

| Structured A-Line Skirts | Denim | 9–12 oz | Holds the architectural shape of the skirt without needing stiff interfacing. |

Critical Design Considerations

1. Designing Tops: The Collar Challenge

- With Denim: You can design structured, stand-up collars. The twill weave supports the interlining, allowing for crisp, sharp necklines that hold their shape even after unbuttoning.

- With Chambray: The fabric is fluid. It works best for “Camp Collars” (Cuban collars) or soft button-downs. If you attempt a stiff, high-stance collar with chambray, it often looks limp or bubbles around the fusing.

2. Designing Bottoms: The Durability Factor

- The Risk with Chambray: We often see designers wanting to make “summer chino” styles out of chambray. Be careful. Because plain weave has lower tear strength, fitted chambray pants often rip at the crotch or seat seams under stress.

- The Solution: If you use chambray for bottoms, choose relaxed silhouettes like culottes or draw-string beach pants where tension is minimal. For anything fitted, stick to lightweight denim.

3. Construction & Seaming

- Denim: Loves “Felled Seams” (double-needle stitching). The fabric bulk creates beautiful highs and lows (puckering) during the washing process, highlighting the construction.

- Chambray: Looks best with clean, flat finishing. We recommend single-needle stitching or clean-finished internal seams to maintain its refined, minimalist aesthetic.

Stylish Alternatives: The Best of Both Worlds

Can you have the look of denim with the feel of chambray? Yes. Through advanced garment finishing, Changhong can treat lightweight denim to feel incredibly soft. We use enzymatic abrasion to break down the fiber’s rigidity, providing a 5 oz denim shirt that looks rugged but feels smooth against the skin.

Bringing Your Vision to the Production Line

Picking the right fabric is the first step. The next step is ensuring those rolls of denim or chambray are cut, sewn, and finished into high-quality garments.

That is where Changhong steps in. We act as an integrated part of your supply chain. We utilize our manufacturing expertise to handle the complex details, from optimizing production for your chosen fabric to executing the most intricate wash effects.

You bring the inspiration; we handle the manufacturing. Let’s work together to produce a collection that meets your standards for quality and design. Contact us today and launch your next exceptional denim project

FAQs

Is chambray just “lightweight denim”?

No. While they share a similar indigo color palette, chambray is a plain weave, while denim is a twill weave. If you look closely, a 5 oz chambray has a simple “salt-and-pepper” texture, whereas a 5 oz denim will still show the characteristic diagonal rib lines.

Does chambray wrinkle more than denim?

Generally, yes. The tight 1/1 plain weave structure creates sharper creases, and because the fabric is lighter, it lacks the weight to “pull” wrinkles out naturally as heavy denim does.

Is chambray 100% cotton?

Traditionally, yes. However, modern chambray often incorporates elastane (Spandex) for stretch or Tencel for better drape. While 100% cotton offers an authentic heritage look, blends are increasingly common in modern denim-style collections.

Which fabric costs more?

Production-wise, denim is often more capital-intensive due to the massive machinery required for continuous indigo rope dyeing. Chambray uses simpler methods. However, the final FOB price depends heavily on the cotton quality (e.g., Pima vs. standard) and the complexity of the wash effects you require.

Can I treat denim to feel like chambray?

Absolutely. This is one of our specialties. Through industrial “bio-polishing” (enzyme washes) and silicone softeners, we can relax the denim fibers significantly. You get the iconic, rugged indigo look, but with a drape that surprises the customer with its softness.