Color fastness refers to how well denim maintains its original color through washing, wearing, and daily use. It’s a key indicator of quality and durability in jeans production. Poor color fastness can cause indigo to fade or transfer, leading to customer complaints and product returns.

This guide walks you through proven, practical steps to reduce indigo bleed and improve your denim’s color fastness. You’ll learn how to stabilize that beautiful indigo color so your products maintain their quality wash after wash, keeping your customers happy and your brand reputation strong.

What You Need to Prepare?

Before you start addressing color fastness issues, you need the right tools on hand. Think of this as setting up your workshop—each piece plays a specific role in helping you understand and fix indigo bleed problems.

| Tool | Purpose | Specifications |

|---|---|---|

| Colorfastness Test Fabric | Reveals indigo transfer during use and washing | White cotton fabric, pre-washed to remove sizing agents |

| Fixing Agents | Strengthens dye-fiber bonds for stable color | Commercial chemical mordants or reactive agents for cellulose fibers |

| Washing Equipment | Simulates laundering conditions to test washing fastness | Washing machine or standardized lab washer with controlled temperature and agitation |

| Rinse and Scouring Chemicals | Removes loose dye molecules to reduce bleeding | Mild detergent and scouring agents suitable for indigo-dyed fabrics |

| UV Exposure Setup | Evaluates light fastness under UV radiation | UV lamp with standardized output or controlled sunlight area |

| Rubbing Test Materials | Measures rub fastness at high-friction points | Standardized rubbing cloths or mechanical abraders (crockmeter) |

| pH Meter | Monitors treatment pH for optimal fixing | Calibrated digital meter with 0.1 pH accuracy |

Step 1: Assess Denim Color Fastness with Standard Tests

Reliable color performance begins with accurate testing. Before making any production adjustments, it’s essential to evaluate how well your denim holds color under real-world conditions. Standardized testing provides measurable data that helps identify the source of indigo bleed and guides improvement across dyeing, washing, and finishing processes.

Perform Washing and Rubbing Tests

Begin with washing fastness tests using white cotton fabric as a control sample. This method replicates what happens when denim is laundered with lighter garments, allowing you to observe dye transfer and fading behavior. Next, conduct rub fastness tests on high-friction areas such as the knees, seat, and inner thighs to assess surface dye stability during wear. Record all observations carefully—these test results form the technical foundation for enhancing your denim’s color fastness.

Next, assess rub fastness on high-friction areas such as the knees, seat, and inner thighs. These zones are most prone to color transfer during regular wear. Use standardized rubbing equipment to apply consistent pressure, then examine the white test fabric for any dye migration. Record the results according to the established crocking scale, creating a clear baseline to guide improvements in dye fixation and finishing processes.

Evaluate Light and Perspiration Fastness

UV exposure is relentless, especially if your customer wears your denim jeans outdoors regularly. Set up light fastness tests that expose sample swatches to controlled UV radiation, mimicking months of sunlight in accelerated conditions. You’ll discover whether your indigo dye breaks down into that faded, washed-out look too quickly, or if it holds strong. Rate your results on the one-to-eight scale, with eight being the gold standard.

Don’t skip perspiration fastness testing—it’s easy to overlook, but human sweat is acidic and can wreak havoc on poorly bonded dyes. Use artificial sweat solutions that replicate real body chemistry, then observe how your denim reacts. If you see significant color loss or dye migration, that’s a red flag that your finishing process needs reinforcement. Compare your findings against industry benchmarks to see where you stand and what you need to fix.

Common Denim Color Fastness Tests and Ratings

To interpret your test results accurately, it’s essential to understand the key denim color fastness tests and their rating systems. Here is a table summarizing common denim color fastness tests and ratings

| Test Type | What It Measures | Common Standard | Rating Scale | Acceptable Level |

|---|---|---|---|---|

| Washing Fastness | Color retention and dye transfer after laundering | ISO 105-C06 / AATCC 61 | 1–5 | Grade 3–4 (commercial), 4–5 (premium) |

| Dry Rubbing (Crocking) | Dye transfer caused by dry friction | ISO 105-X12 / AATCC 8 | 1–5 | Minimum Grade 3, Grade 4 preferred |

| Wet Rubbing (Crocking) | Dye transfer under moisture and friction | ISO 105-X12 / AATCC 8 | 1–5 | Grade 2–3 acceptable for indigo denim |

| Light Fastness | Resistance to fading under UV or sunlight | ISO 105-B02 / AATCC 16 | 1–8 | Grade 4+ daily wear, 6–7 outdoor use |

| Perspiration Fastness | Color stability against acidic and alkaline sweat | ISO 105-E04 / AATCC 15 | 1–5 | Grade 3–4 recommended |

| Water Fastness | Dye stability when exposed to water | ISO 105-E01 | 1–5 | Grade 3+ for finished denim |

| Sea Water Fastness | Resistance to saltwater exposure | ISO 105-E02 | 1–5 | Relevant for resort & summer denim |

Step 2: Apply Fixing Agents to Improve Color Stability

After evaluating your denim’s color performance, the next step is to stabilize the indigo on the cotton fibers. Using appropriate fixing agents or reactive dyes strengthens the bond between dye and fabric, reducing bleeding and fading during washing and wear.

Choose and Use the Right Mordants

Select reactive dyes or mordants formulated specifically for indigo and cotton. Select reactive dyes or mordants formulated specifically for indigo and cotton. Typical concentrations range from 1–3% of the fabric weight (owf), but it’s important to adjust based on the dye type, fabric density, and small-scale test results. Apply evenly across the fabric, and ensure the chemical penetrates the yarn, not just the surface. Consider environmental and safety guidelines when handling these agents to maintain both product quality and responsible manufacturing practices.

Incorporate Rinsing and Scouring Processes

After applying fixing agents, rinsing and controlled scouring become your quality insurance. These processes remove loosely bound dye molecules that would otherwise continue to bleed in future washes. You’re essentially cleaning up the excess so only the well-fixed indigo remains.

Your approach should include:

- Thorough rinsing in clean water to flush out unfixed dye particles and residual chemicals from the mordant treatment.

- Controlled scouring using mild alkaline solutions to enhance dye fixation without compromising the fabric’s integrity or hand feel.

- Monitoring pH levels throughout the process—aim for slightly alkaline conditions (pH 7.5-9) for optimal results without causing fiber damage.

- Checking water temperature and agitation levels to balance effective cleaning with fabric preservation.

Step 3: Execute Quality Control and Final Testing

Re-Test for Color Fastness After Treatment

Once you’ve applied your finishing treatments, it’s time to validate their effectiveness. Run the same battery of tests you performed initially:

- Washing fastness to confirm color retention through multiple laundry cycles

- Rubbing (crocking) tests to verify reduced color transfer

- Light fastness assessments to ensure UV resistance improvements

- Perspiration fastness checks to evaluate performance against body chemistry

Compare your new results against the baseline data you collected before treatment. Document everything meticulously. If results fall short, adjust your treatment parameters and test again.

Custom Denim Tailored to Your Brand’s Vision

Partner with a trusted denim manufacturer offering full control from fabric to finish. Benefit from flexible order sizes, sustainable materials, and hundreds of fresh styles monthly to bring your unique denim designs to life.

Denim Dyeing Methods and Effects Explained

Denim color performance starts with the dyeing method. Different approaches to applying color affect penetration, fastness, and the fabric’s behavior in wear and washing. Understanding these methods allows you to choose the right process for both aesthetic and durability goals.

Comparison of Dyeing Techniques

- Fiber dyeing: Colors cotton before spinning, achieving deep penetration and consistent tone.

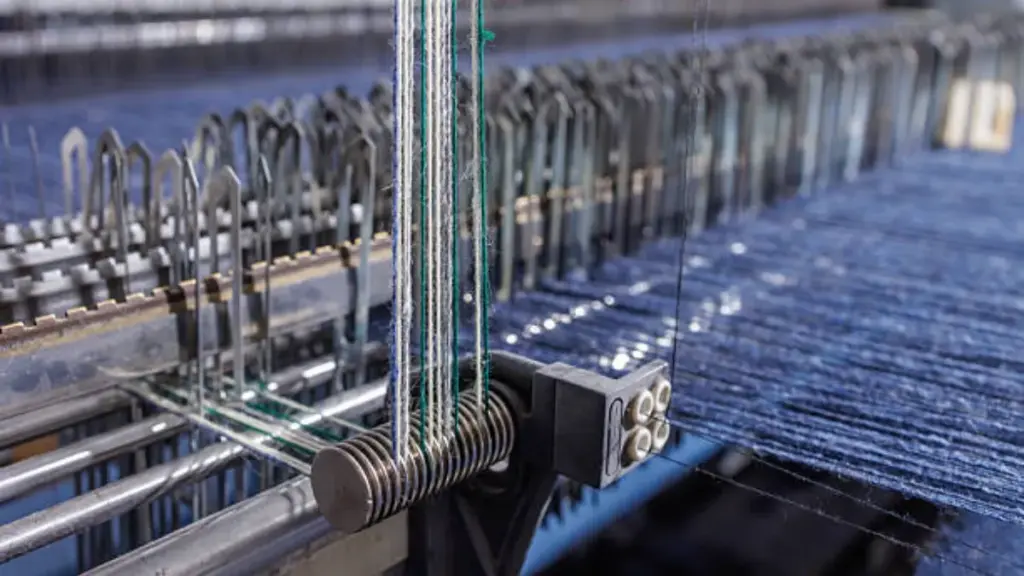

- Yarn dyeing: Classic denim method; indigo coats yarn bundles, creating the characteristic blue exterior and white core.

- Piece dyeing: Colors woven fabric, often for uniform shades or fashion effects.

- Garment dyeing: Colors finished jeans for unique tones and effects.

For color fastness, the choice of dye chemistry is critical:

- Vat dyes (indigo): Sit on the fiber surface, allowing controlled fading but prone to bleed.

- Reactive dyes: Form stronger bonds with cotton, improving wash fastness.

- Acid and disperse dyes: Target protein fibers or synthetics; less relevant for traditional denim.

Impact of Wet Processing and Finishing

Wet processing and finishing steps directly influence color stability:

- Scouring: Removes waxes and impurities for better dye absorption.

- Bleaching: Lightens the fabric but can weaken fibers.

- Mercerizing: Swells fibers to improve dye uptake and fastness.

Finishing treatments help stabilize color and reduce transfer:

- Fixing agents and resins: Strengthen dye attachment.

- Softeners: Maintain hand feel while minimizing color rub-off.

Sustainable wet processing is increasingly important. Optimizing chemical dosing, reducing water use, and selecting eco-friendly auxiliaries improves both environmental performance and product quality.

Common Mistakes and Expert Tips to Avoid Indigo Bleed

You’ve worked hard to source quality denim, but if indigo bleed ruins your reputation, all that effort goes to waste. The good news? Most color fastness issues stem from preventable mistakes during manufacturing and finishing. Let’s walk through the most common pitfalls and the expert solutions that’ll keep your denim looking sharp wash after wash.

| Common Mistake | Solution / How to Avoid |

|---|---|

| Insufficient rinsing leads to loose dye residue | Implement multiple controlled rinses with appropriate agents. You’re aiming to remove all unfixed indigo particles that sit on the fiber surface. Don’t rush this step—loose dye is the number one culprit behind crocking and color transfer. |

| Using direct dyes without mordants causes poor fixation | Opt for reactive or vat dyes with proper mordant treatments. Indigo naturally forms weak van der Waals forces with cotton, not the strong covalent bonds you need for lasting color. Mordants bridge that gap and dramatically improve wash fastness. |

| Ignoring rub fastness testing increases crocking risk | Conduct standardized rub tests and adjust finishing accordingly. Denim faces constant friction at stress points like knees and seat areas. If you skip this test, you won’t catch crocking issues until your customers complain about stained furniture and skin. |

| Overexposure to sunlight degrades color fastness | Use UV stabilizers or finishings to improve light fastness. Denim garments spend a lot of time outdoors, and UV radiation breaks down indigo molecules faster than you’d think. Protective finishes rated on the eight-point light fastness scale keep your blues vibrant longer. |

| Skipping perspiration fastness assessment | Test and ensure dye stability to sweat exposure for wearer safety. Jeans sit directly against skin, and poor perspiration fastness means dye molecules can shed and potentially transfer harmful substances. This isn’t just about aesthetics—it’s about protecting your customers. |

Maintaining Color Fastness After Purchase

Proper garment care is essential to maintain denim’s color and longevity. Follow these strategies to reduce fading and bleeding:

- Turn jeans inside out before washing – protects the outer surface from friction and reduces dye loss.

- Use cold water and gentle detergents – avoid hot water, bleach, or optical brighteners.

- Limit washing frequency – wash only when visibly soiled or after 5–6 wears.

- Air-dry instead of machine drying – heat can accelerate dye release.

- Store away from direct sunlight – UV exposure degrades indigo over time.

- Avoid prolonged soaking – minimizes dye migration during washing.

Bringing It All Together

By now, you understand how to evaluate, stabilize, and preserve your denim’s color, turning potential indigo bleed into predictable performance. Careful testing, proper finishing, and consistent garment care together ensure durable, vibrant denim.

At Changhong Jeans, established in 2004, we combine advanced production capabilities with continuous innovation to deliver high-quality, customizable denim. Our integrated factory enables rapid style launches and precise color control, ensuring each pair meets professional standards and brand expectations.

Ready to provide your customers with premium, color-stable denim? Explore our custom denim solutions and submit an inquiry →

Frequently Asked Questions About Color Fastness

What is crocking and how does it affect denim quality?

Crocking is when indigo dye rubs off from denim onto other surfaces through friction. It happens because indigo forms weak bonds with cotton fibers, so the color transfers easily during wear and damages your furniture or other clothes.

How can dark denim bleeding be minimized during wear?

You can reduce bleeding by washing new dark denim separately in cold water with vinegar before the first wear. Look for jeans that use reactive dyes or have been treated with mordants, as these create stronger chemical bonds that resist color loss.

Which denim fabric types are more prone to color bleed?

Raw and selvedge denim with direct dye applications bleed the most because they lack finishing treatments. Denim dyed only with traditional indigo is also vulnerable since it relies on weak van der Waals forces instead of covalent bonds.

What are the industry standards for denim color fastness?

Washing fastness is rated from one to five, while light fastness uses a scale from one to eight. Higher numbers mean better resistance, and quality denim should achieve at least a grade three or four to meet international manufacturing standards.

How effective are factory rinse washes in stabilizing color?

Factory rinse washes remove loose surface dye and improve immediate color stability. They’re effective for reducing initial bleeding, but long-term fastness depends more on the dye chemistry and finishing treatments applied during production.