Sourcing authentic Japanese selvedge denim is a technical minefield. Browsing catalogs is the easy part; the real headache is making the math work. When you choose vintage loomstate fabric, you are signing up for narrow widths that double your consumption costs and unpredictable shrinkage rates that threaten your size charts.

For a brand owner, the stakes are high. A single calculation error can turn a size 32 into a size 30, while the wrong texture will be instantly spotted by denimheads. This guide cuts through the noise, breaking down the true economics of premium denim and the specific technical questions you must ask to verify authenticity.

Why the World is Obsessed with Japanese Denim

Why are customers willing to pay a premium for Made in Japan or Japanese-style denim?

It comes down to aging potential.

Mass-market denim is chemically fixed to ensure the color never changes. Authentic Japanese denim does the opposite. By combining unstable rope dyeing with the irregular texture of vintage weaving, the fabric creates high-contrast fades that pre-washed mass-market denim simply cannot replicate. You are selling a fabric that improves with wear, which is the primary justification for a $200+ retail price point.

What You Are Actually Paying For

You might look at a price tag of $15 or $20 per yard and hesitate. But the brand name isn’t the main cost driver. You are paying for inefficiency.

The Cost of Shuttle Looms

Modern projectile looms shoot weft yarns across the fabric at high speeds. They are efficient and produce flawless, flat fabric.

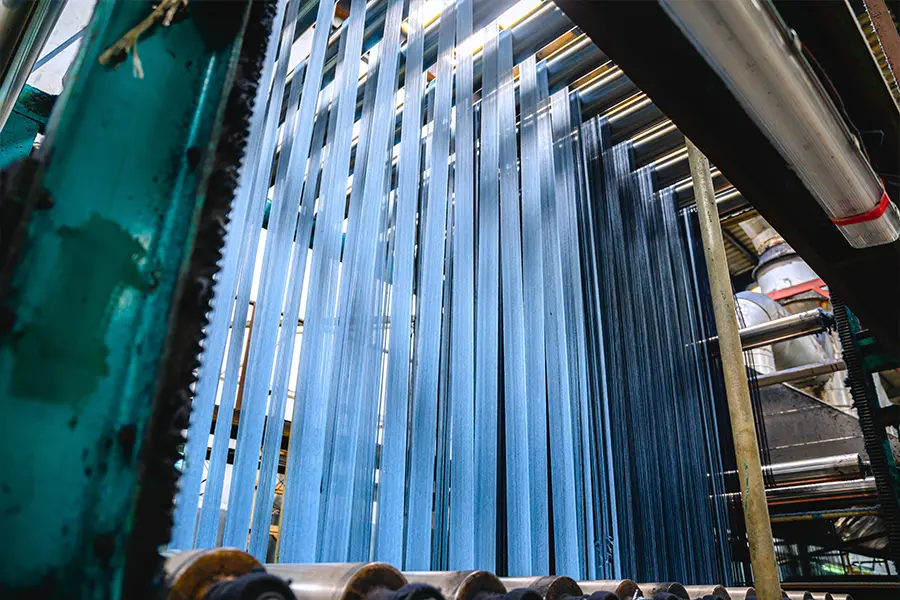

Vintage Toyoda shuttle looms are different. They pass a wooden bobbin back and forth physically.

- The Technical Impact: These looms vibrate and weave at a much lower tension. This slowness creates a fabric surface that is slightly irregular and slubby. You simply cannot fake this texture with modern machines.

- The Output Cap: One shuttle loom might produce only 15 to 20 meters of fabric a day. A modern loom produces hundreds. That scarcity drives the price.

- The Edge: This continuous motion creates the tightly woven selvedge ID that prevents fraying.

Rope Dyeing: The Core Difference

If you unravel a yarn of cheap denim, it is blue to the core. With Japanese selvedge, the center is white. This is rope dyeing. Yarns are twisted into ropes and dipped in indigo, then oxidized. The dye sits only on the surface. This process is technically difficult to control, but it is the only way to achieve the high-contrast whiskers and honeycombs that enthusiasts demand.

Elevate Your Brand with Custom Denim Manufacturing

How to Choose Between Unsanforized and Sanforized

When sourcing Japanese selvedge, you must decide on the finishing state regarding shrinkage management. This choice directly affects your pattern grading and returns rate. Compare the two options below to decide which fits your production capabilities:

| Feature | Unsanforized Loomstate | Sanforized Pre-Shrunk |

|---|---|---|

| Definition | True raw denim straight off the loom. No steam or chemical treatment. | Steam and roller treated to stabilize dimensions. |

| Shrinkage Risk | High 8–10%. Unpredictable without testing. | Stable <3%. Dimensions are locked in. |

| Texture & Feel | Hairy, extremely rigid, distinct leg twist skew. | Smoother, flatter surface, consistent handfeel. |

| Pattern Grading | Complex. You must grade patterns significantly larger to account for shrinkage. | Standard. You can use standard pattern sizing. |

| Best For | Hardcore heritage reproductions & purists. | Scalable modern production & predictable fits. |

Pro Tip: If you are a new brand, start with Sanforized. It minimizes the risk of sizing errors while still delivering the rigid raw denim experience.

The Real Cost of Premium Denim

Let’s be realistic about the budget. Why does a pair of selvedge jeans cost you so much more to make?

1. Fabric Consumption

- Standard wide denim: Measuring 58 to 60 inches wide, you can nest pattern pieces efficiently. Usage is typically around 1.5 yards per pair.

- Selvedge denim: Measuring only 28 to 32 inches wide, you are forced to place the outseam precisely on the edge. You cannot rotate pieces to save space. Usage jumps to 2.5 to 3.0 yards per pair.

2. Cutting Room Labor

You cannot easily stack 100 layers of selvedge denim and cut them all at once. The selvedge edge might not align perfectly on every layer. It often requires slower, more careful spreading and cutting to ensure the cuff looks perfect.

The Bottom Line: You are paying three times the price per yard and using double the amount of fabric. This high cost structure is unavoidable for authentic selvedge, but it is necessary to command a premium market position.

How to Spot Authentic Japanese Quality

Don’t rely solely on the red line selvedge ID. Cheap mills worldwide can stitch a red thread on the edge. To confirm you are dealing with high-grade Japanese selvedge denim or its equivalent quality, you need to look closer.

Here is the 3-step inspection used by veterans:

1. The Unravel Test for Rope Dyeing: Pull a single warp yarn from the raw fabric and untwist it.

- The Fake: The yarn is blue through and through, indicating cheap sulfur or sheet dyeing. This will fade flat and muddy.

- The Authentic: The yarn has a deeply indigo exterior but a crisp white core. This is the hallmark of genuine rope dyeing, the specific Japanese technique required for high-contrast fading.

2. The Slub Texture and Loom Character: Hold the fabric up to the light at an angle.

- The Fake: The surface looks perfectly uniform, like a grid. This is modern projectile loom fabric.

- The Authentic: You see irregular bumps known as slub and tiny white cotton knots called nep. Authentic Japanese selvedge is intentionally inconsistent. This wabi-sabi texture comes from the low-tension chatter of vintage shuttle looms, creating the vertical fading streaks collectors call tate-ochi.

3. The Density of the Selvedge ID: Inspect the white and red edge itself.

- The Fake: The edge feels loose, wavy, or ruffled compared to the body of the fabric.

- The Authentic: The selvedge line should be tight, flat, and dense. Japanese mills tune their looms to ensure the edge tension is perfectly balanced with the fabric body, ensuring it lies flat on the jean outseam.

Sourcing Strategy: The 3-Question “Litmus Test”

If you decide to look outside Japan to improve your margins and lead times, you must be vigilant. Many suppliers claim to sell “vintage selvedge,” but they are selling modern, high-speed denim fabric with a stitched edge.

To ensure you are buying authentic quality, ask any potential partner these three technical questions. If they stumble, walk away.

1. “What is the RPM of your looms?”

This is the ultimate lie detector. Authentic vintage shuttle looms must run slowly, typically between 130 and 160 RPM. If they are running at 400+ RPM, they are using modern projectile looms. Speed kills texture. If they can’t tell you the speed, they aren’t the manufacturer.

2. “Do you use rope dyeing or slasher dyeing?”

For that high-contrast fade, rope dyeing is non-negotiable. It is the only method that reliably keeps the core of the yarn white. Slasher dyeing often results in dye penetrating too deeply, creating a flat, muddy fade later on. Ask for a cross-section photo of the yarn.

3. “Can I develop a custom weight under 1,000 yards?”

True heritage mills often demand massive Minimum Order Quantities of 3,000+ yards. A smart alternative partner should offer the agility to test new fabrics with lower risk. If they demand huge volumes upfront, you are losing the advantage of switching away from the big mills.

Final Thoughts

Sourcing premium selvedge is a balancing act between art and commerce. You need authentic character to define the category, but you also need a supply chain that actually functions.

Changhong is a powerful denim garment manufacturer specializing in end-to-end customization. Instead of limiting you to stock options, we execute complex developments tailored to your brand’s requirements.

Whether you need to develop a proprietary fabric blend, engineer a heavyweight 21oz collection, or execute a complex vintage wash, our R&D team makes it happen. We provide the manufacturing backbone that allows you to scale up without diluting your product’s quality. If you are ready to build a denim collection that rivals the best in the world, we are ready to be your partner.

Frequently Asked Questions

What is the difference between raw and selvedge?

Selvedge refers to the edge and how it is woven. Raw refers to the unwashed state of the fabric. You can buy selvedge denim that has been washed and feels soft, or you can buy wide-loom denim that is raw and feels hard. The gold standard for enthusiasts is usually both: raw selvedge denim.

Is heavier denim like 21oz always better?

No. It is simply heavier. Heavyweight denim is a niche market for hardcore enthusiasts. For a standard fashion collection, 12oz to 14.5oz is the sweet spot. It is substantial enough to feel expensive but comfortable enough for daily wear.

Why does the blue dye rub off on hands and shoes?

This is called crocking, and it is a sign of quality, not a defect. Because rope-dyed indigo sits on the surface of the yarn, it rubs off easily until the fabric is broken in. This instability is exactly what allows the jeans to fade personally to the wearer.

Why do the leg seams twist on my samples?

This is known as leg twist, and it is a common characteristic of unsanforized denim. Because the fabric has not been skew-stabilized, the tension in the weave releases in the direction of the twill (usually clockwise). Heritage enthusiasts consider this a desirable feature of vintage authenticity.

What care instructions should I put on the label?

To preserve the rigid feel and high-contrast fading potential, recommend “Wear Often, Wash Seldom.” Advise customers to wash inside out in cold water and hang dry. Warn them that using a dryer will destroy the leather patch and alter the fit of the selvedge line.